- JTEKT TOP

- Sustainability

- Environmental Report

- Product/Technologies

Product/Technologies

The impact on environment by using product is deeply related to product development and design. Companies have a responsibility to develop technologies to reduce their environmental impact and to design products that are easy to reuse and recycle, considering the entire products' life cycle from material procurement to the use and disposal by customers.

JTEKT believes that our products and technologies directly and indirectly provide environmental countermeasures for our customers' products and manufacturing processes and, as such, greatly contribute to the environment. Therefore, we endeavor to improve the environmental performance of each product through the product lifecycle, and are contributing to the prevention of global warming and the effective use of resources as we strive to achieve a sustainable society.

Main FY2022 results

Results evaluation

| Classification | Initiative Items | Target and initiative policy | FY2022 Activity Result | Assessment | |

|---|---|---|---|---|---|

| Products and Technologies | Development and design of environmentally friendly products | (1) Development of new technology and products that promote environmental impact reduction of top runners | Deploy the environmental efficiency formula established by JTEKT to each group company, aiming to improve the assessment of our products as All-JTEKT |

|

◯ |

| (2) Promotion of 3R (reduce, reuse, recycle) design with consideration for effective use of resources | ①Prompotion of the product design easily recyclable ②Reduction of resource and energy consumption by downsizing, weight-saving, and lengthening product life |

|

|||

| (3) Management and reduction of environmentally hazardous substances contained in products | Promotion of global chemical regulation compliance and establishment of management |

|

|||

| (4) Deployment of environmental assessment at the design and development stages | Promotion of environmentally friendly products through environmental assessment at the design and development stage |

|

|||

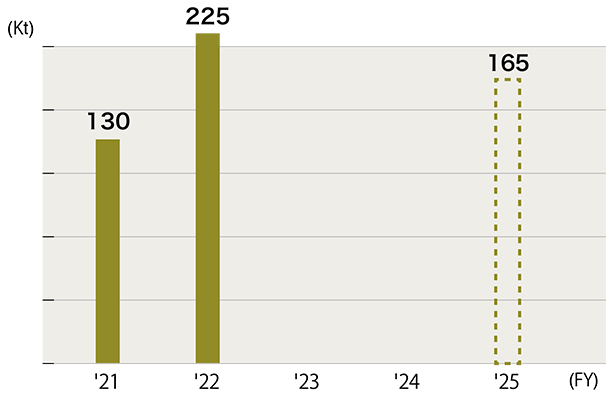

| (5) Contribution to CO2 reduction by products | ①Reduction of CO2 emissions by switching to environmentally friendly products ②CO2 reduction contribution from product use shall be at least 165K-ton by FY2025 (Global contribution to annual CO2 reduction) FY2022 target: 116K t-CO2 or more |

||||

Activity report

Promotion by Environmental Responsive Products Subcommittee

The Environmental Responsive Products Subcommittee promotes development of environmentally-friendly products together with the domestic group companies. Innovative technology is incorporated in the development and design stages to make products smaller, lighter, and more efficient, as well as reduce the usage amount of environmentally hazardous substances and raw materials. In this way,JTEKT is engaging in environmental conservation on a global scale through its products.

Contribution to CO2 reduction by products

JTEKT is working to improve the efficiency of its products with a goal of contributing to the reduction of CO2 emissions by 165Kt or more by FY2025. The result of FY2022 was 225Kt.

*Contribution to CO2 reduction by products is the amount calculated globally in a single fiscal year.

Assessment method

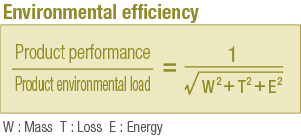

In order to make the environmental load reduction effect of our products evaluated numerically, we have established its basic formula for environmental efficiency as our own index. The higher the value, the greater the environmental impact reduction. Therefore, we set the target of a higher environmental efficiency value each year, and work on product development while evaluating the degree of achievement.

- Basic formula for environmental efficiency and environmental efficiency computation

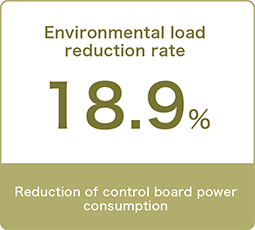

Environmental efficiency is a value calculated based on the degree of lightness, compactness, energy-savings, etc. The environmental efficiency value is calculated by dividing the environmental efficiency of the assessed product by that of the standard product. - Computation of environmental load reduction effects

Environmental load reduction effect is determined by calculating the environmental load reduction rate from the environmental efficiency value. For example, if the environmental efficiency value is 1.25, the environmental load reduction effect of the product is 20%, and the reduced environmental load is calculated as the reciprocal of the envirnmental efficiency value.

Main implementation contents

TEKT Corporation : Industrial and Bearing Business Unit

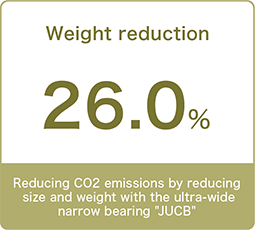

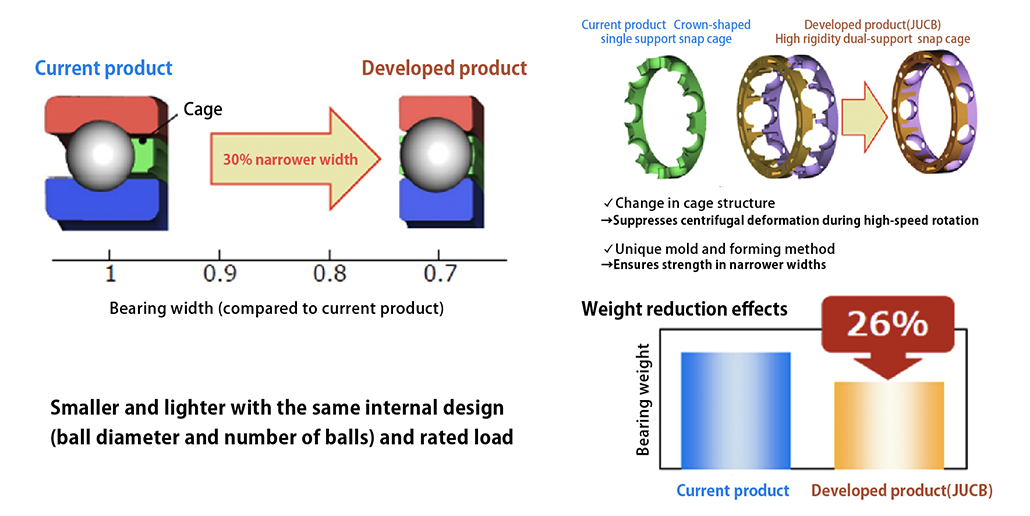

Reduced CO2 emissions by reducing size and weight with the ultra-wide narrow bearing " JTEKT Ultra Compact Bearing "

Following with automotive electrification growth trend, development and production of eAxle, which integrate inverter, motor, and reducer including differential, is growing rapidly worldwide. In order to develop BEV, the eAxle, which is the heart of eDrive system, is required to be smaller.

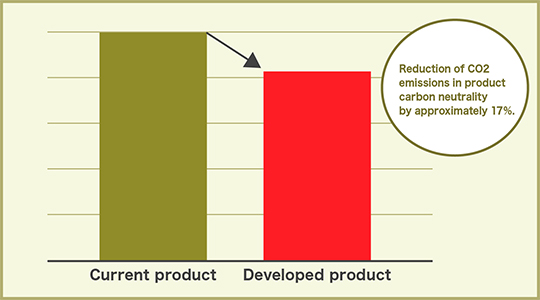

The newly developed product, based on a high-rigidity combination resin cage, has realized a narrowing of the width of the bearing by providing holes in the middle of the side of the cage, making it as small as possible. As the result of this downsizing and lightening, we have succeeded in reducing CO2 emissions in product carbon neutrality (including during manufacturing) by approximately 17%.

<Effects of Initiatives>

By applying it to to general-purpose size, axial dimension is shortened by approximately 30% and weight is reduced by approximately 26%.

Bearing performance (strength, durability) is equivalent to that of conventional products, and bearing width is narrowed to the utmost limit compared to conventional products. When applied to general-purpose size, axial dimension is reduced by approximately 30% and weight is reduced by approximately 26%. This makes it possible to shorten the unit length by installing it on a coaxial type or 3-axis type eAxle.

Reduction of CO2 emissions in product carbon neutrality (including during manufacturing) by approximately 17%.

By downsizing and weight reduction of the bearing, we have reduced COBy downsizing and weight reduction of the bearing, we have reduced CO2 emissions in product carbon neutrality (including during manufacturing) by approximately 17%. emissions in product carbon neutrality (including during manufacturing) by approximately 17%.

We will continue contributing to electrification to achieve carbon neutrality.

My SDGs

Machine Tools & Manufacturing Systems Business Unit

Strategic Planning & Management Dept.

Pursuit of energy savings with OneJTEKT

Machine tools are equipment that require a great deal of energy to form the workpiece into the desired shape. However, the energy input to machine tools also includes energy that is not used directly in machining, and this wasted energy that is not used in machining must be reduced. To achieve this, it is essential to collaborate not only with sales, design, procurement and manufacturing, but also with research departments and JTEKT Group companies. Our department will be the linchpin of this wasteful energy reduction activities, and we will continue to take on the challenge of pursuing energy saving in processing machines with OneJTEKT.