- JTEKT TOP

- Sustainability

- Social Report

- Together with employees

- Safety and health-related initiatives

Together with employees -

Safety and health-related initiatives

Basic concept of JTEKT

To create a safe and comfortable work environment

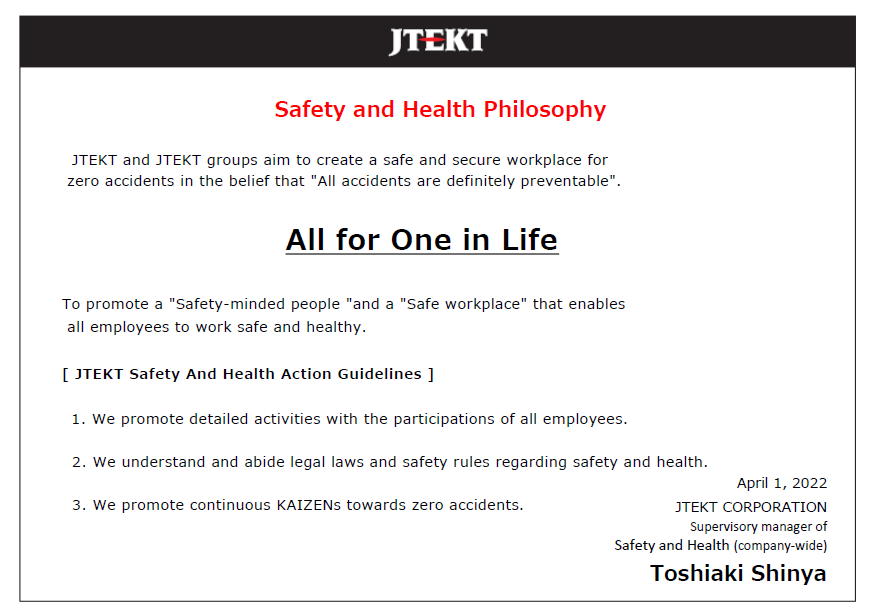

"All accidents can be prevented" is the company-wide safety and health philosophy in JTEKT, and all employees are united in their efforts to participate in safety and health activities and create a comfortable work environment.

In addition, a dedicated Global message, ʺAll for One in Life,ʺ is expressed as the company safety philosophy.

ALL JTEKT aims to achieve zero accidents through activities focusing on one's life and health, taking into account the laws and regulations of each region and the industry's issues.

Safety and Health Promotion Structure

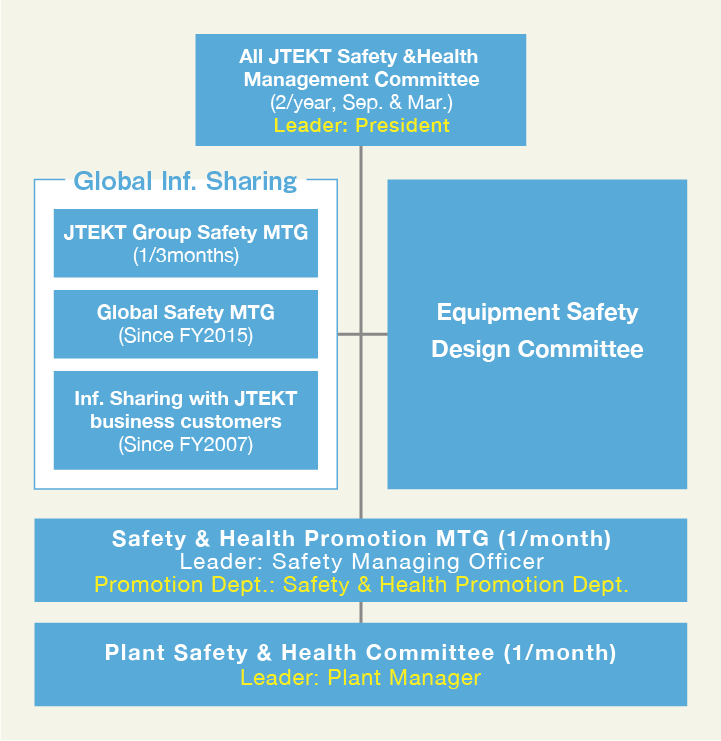

In order to create a healthy, safe, secure, and comfortable work environment for all employees, we have established a company-wide Safety and Health Committee chaired by the President and consisting of members of the Safety and Health Affairs Secretariat of each plant and office, including management, to establish a centralized management system for safety and health, including domestic and overseas group companies, and to develop safety and health activities under the One JTEKT concept.

The company-wide Safety and Health Committee is held twice a year, at the middle and end of the fiscal year, to share policies on safety, health, and fire prevention and to confirm those progresses based on the review of safety scores and employees' opinions, and the results are shared with all employees. As an organization that complements the activities of the company-wide Safety and Health Committee, the company-wide Safety and Health Promotion Meeting is held every month. In addition to messages from top management on safety and the progress of annual policies, we share accident reports as well as the recurrence preventions in a timely manner. In each plant and office, a Safety and Health Committee chaired by the plant manager is established based on the Safety and Health Activity Guidelines. In addition to the implementation and confirmation of safety and health activities and discussions between labor and management regarding employee issues, the committee also reports on safety and health activities suited to the characteristics of each plant and office and the results of safety and health patrols involving everyone from plant managers to associates, to identify issue areas and discuss Kaizen plans.

In the event of an accident, we will inform management as quickly as possible and do our utmost to prevent the recurrence of the accident and prevent it from happening again by assisting in the rescue of victims and helping them return to work.

Safety and Health Control System

Main Initiatives in FY2022

[ JTEKT Safety Activities ]

Safety Minded People Evaluation

We visualize the strengths and weaknesses of each workplace and individual employee through the safety evaluation of each and every JTEKT employee. Based on the results of the evaluation, supervisors communicate with their subordinates to eliminate their weaknesses, aiming to create people and workplaces with a high level of safety awareness and ability in order to achieve zero accidents.

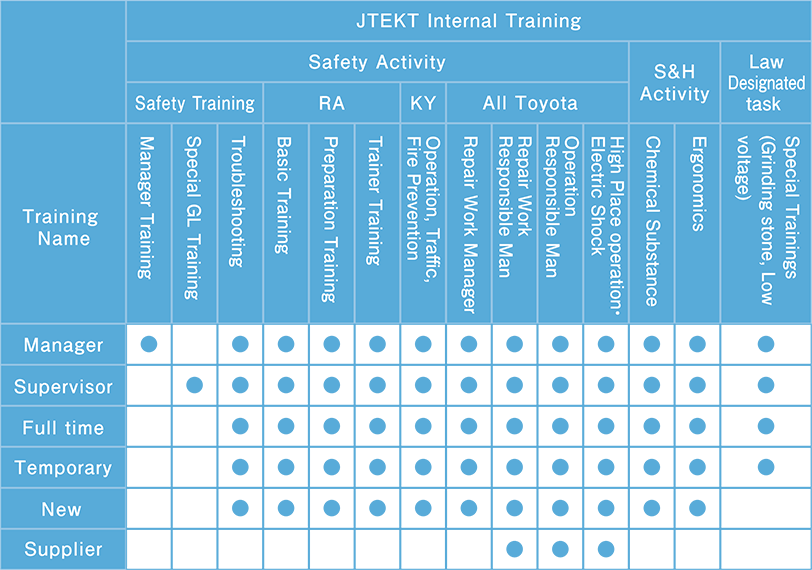

Enhancement of Safety Training

We are striving to develop human resources who will prevent accidents from occurring by systematically promoting safety education and training.

As part of our initiatives for FY2022, we are increasing new training, especially for supervisors and managers, who are the key personnel onsite, to enhance our training even further.

Safety of Machinery and Equipment

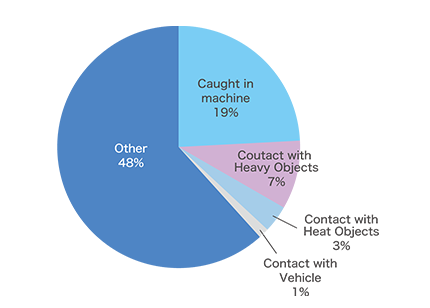

Regarding the safety of machinery and equipment, we are continuing to take measures for equipment with a risk of being "caught in machine" as one of the serious six accidents that could cause severe disabilities that we have been working on.

In addition to that, we also consider the other serious six accidents to be major issues and are working to address them.

We have been mainly conducting patrols and safety checks in our own workplaces, but we are now promoting cross-checks between departments. By incorporating new perspectives, we are preventing overlooks due to habituation and improving overall safety awareness.

*Serious 6 Accidents: Six categories of accidents with high risk of serious accidents as defined by the All Toyota Safety and Health Study Group Caught in machine, contact with heavy objects, contact with vehicles, falls, electric shock, and contact with high heat objects.

Personal Protective Equipment

Regarding protective equipment, appropriate protective equipment is selected at each workplace and workers are instructed to wear protective glasses, safety shoes, helmets, cut-resistant gloves, etc. as necessary based on the guidelines of the company rule.

Safety Culture Diagnosis

Each workplace operates its safety and health management system in accordance with the OSHMS guidelines of the Ministry of Health and Welfare. To raise the level of the management system and foster a better safety culture, we continuously conduct "Plant Safety Culture Diagnosis," an audit that mainly consists of awareness survey and on-site actual condition evaluation.

※OSHMS:Occupational Safety and Health Management System

Ensuring the Safety of Contract Construction on the Premises

In addition to the safety standards common to the Toyota Group, JTEKT has established its own safety standards, including the establishment and operation of a construction manager system to ensure the safety of contract construction performed on JTEKT's premises, to prevent accidents from occurring.

Promoting Work based on Ergonomics

We are promoting work Kaizen by utilizing an ergonomics-based work evaluation system. In addition, we are also working to improve the weight restrictions set in our regulations, especially with regard to the weight that can be carried with hands.

Workplace Environment and Chemical Substances

In order to create a safe and healthy workplace for all employees, we measure the work environment twice a year in accordance with laws and regulations related to occupational safety and health at workplaces where noise and dust are generated by machining, where heat is generated in heat treatment processes, and where chemical substances are handled to maintain and perform Kaizen. We will also protect the safety and health of our employees by creating a workplace structure for voluntary chemical substance management and promoting a healthy and lively workplace.

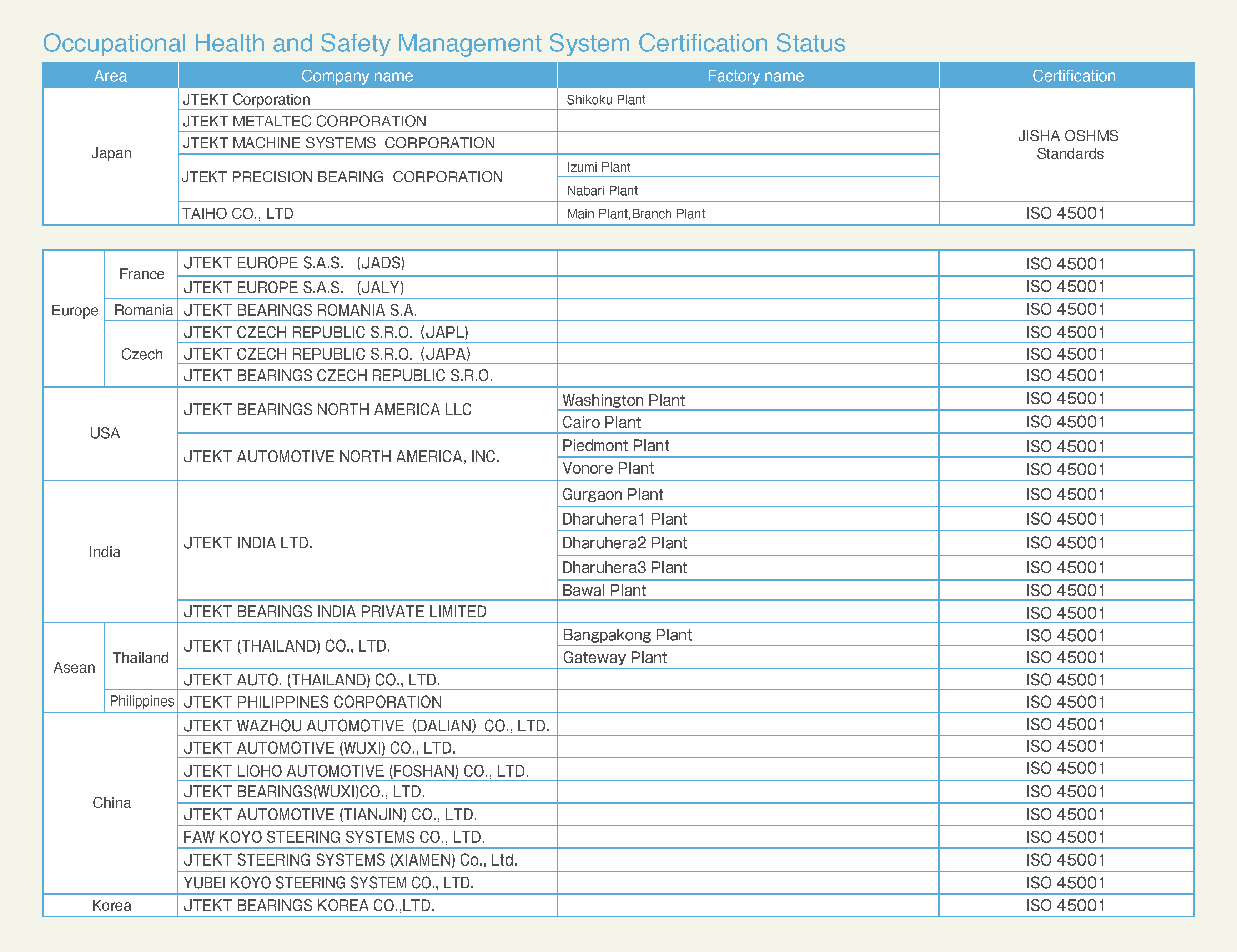

Certification Status of Global Management System

In Japan, one of JTEKT's plants has acquired JISHA Occupational Safety and Health Management System (OSHMS) certification, and the remaining plants have established and are operating their own occupational safety and health management systems based on OSHMS standards. In the JTEKT Group in Japan and overseas, three domestic companies have obtained external certification for JISHA OSHMS, and 29 overseas plants have obtained external certification for ISO 45001.

Fire Risk Reduction Activities

Fire leads a significant negative impact on both the customers and the supplier chain if the production is stopped. JTEKT has established rules for fire prevention management focusing on flammable materials and fire source, and JTEKT is working to improve fire prevention measures by sharing information on fires that have occurred within the Toyota Group and conducting Yokoten and investigations within the JTEKT Group.

Global Initiatives

In collaboration with the person in charge of safety at each company, we provide support through cross-sectional activities in safety & health and fire prevention by holding periodic meetings, and so on.

Particularly in regions where there are many overseas bases, such as Europe, North America, China, and ASEAN countries, we have regional headquarters in each region to provide enhanced support.

As our main initiative, we are working on standardization of work and preparation of procedure manuals to prevent accidents in the first place, and on fire prevention, we are preparing management forms and conducting self-inspections.

In the event of an accident or a fire, a debriefing meeting is held with JTEKT, and the details of the accident are shared globally.

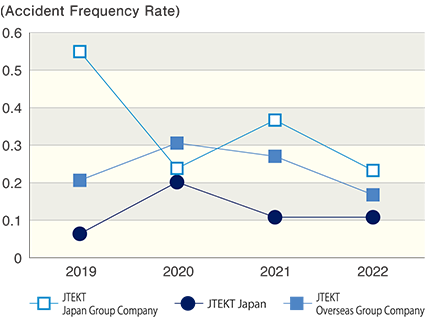

Lost Time Accident Frequency Rate※

![]()

[ Initiatives in FY2023 ]

Enhancement of Safety Training

We will brush up the content of the training for managers and supervisors, which started in FY2022, and share it to the targeted employees.

Safety of Machinery and Equipment

We will continue to promote inter-departmental cross-checks, and based on the serious 6 accidents, we will also work on risks that have tended to be overlooked. With regard to the risks that have been identified, we will work on visualization of the risks to the workers as the first step.

Safety Culture Diagnosis

We will work to improve the safety culture diagnosis which is currently in operation. In order to clarify issues of each workplace, we will review our evaluation methodology to specifically focus on weaknesses (lowest rated workplaces) and make specific proposals to the workplaces for further improvement.