Development and start of volume production of ultra-thin

deep-groove ball bearing (high load capacity type)

JTEKT Corporation (hereinafter called “JTEKT”) has newly created a tagline “Key of your operation Koyo” for the bearing brand “Koyo”. JTEKT contributes to every industry as an indispensable partner to solve customers' problems through working with customers and to provide benefits.

JTEKT has developed and begun volume production of an ultra-thin deep-groove ball bearing where improvements were made in both size reduction and increased capacity (longer life) which are normally contradictory goals.

(We have achieved “smaller size” by a reduction of thickness and “higher load capacity (longer life)” by increasing the number of rolling elements as compared to the conventional type of bearing.)

Being aware of such requirements is essential to us as a provider of happiness to manufacturers and general customers, as we proceed with the pursuit of better engineering and promote the development of better products together with customers.

1.Features

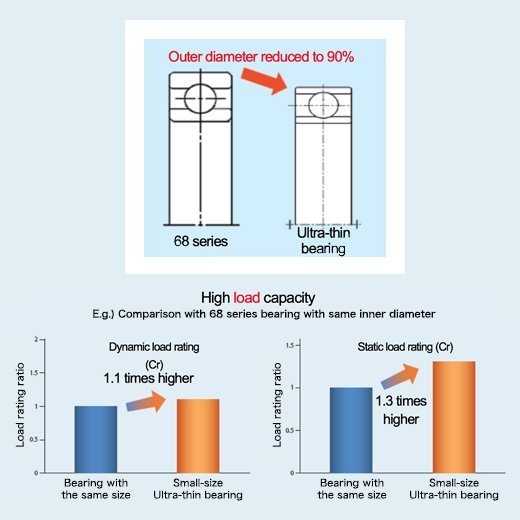

(1) Smaller size by reduction of bearing ring thickness

With machining accuracy secured at a level that allows further thickness reduction, the thickness of the bearing ring was reduced by approximately 50% compared with a conventional type (68 series).

The outer diameter was reduced to 90% of its former dimension.

* Raceway surface: area where rolling elements (balls) make contact with the inner surface of the outer ring and the outer surface of the inner ring

(2) Higher load capacity (longer life) by increasing the number of rolling elements

Adoption of a new manufacturing method increased the number of rolling elements held.(The ball packing factor was increased by approximately 50% compared with a conventional type (68 series).)

Accordingly, the dynamic load rating was improved by 10% and static load rating by 30%, resulting in longer life (approximately 1.3 times longer as calculated by JTEKT based on the increase in the dynamic load rating)

2.Detailed description

In recent years, the robot market is rapidly expanding mainly in Asia. Lively demand is expected especially for robots in the manufacturing business (related to automobile, smartphone/tablet) and non-manufacturing business (nursing care, household). With regard to robots used in manufacturing situations, there is always a demand for smaller occupied floor space, and for robots used in nursing care and household business small size, long life and energy saving are in demand for convenience reasons.

Bearings for robot components are required to have similar performances. However, since small size and high capacity (long life) are contradictory goals, achieving both of them at the same time is always a difficult problem but what customers require.

(Bearings normally need to be larger to withstand higher load.)

In response to this requirement, JTEKT took on this challenging problem, and has achieved both size reduction and capacity increase at the same time.

To reduce the bearing thickness, machining accuracy in the manufacturing process needed to be improved. Through improving and devising the way of manufacturing, we reduced the thickness of the bearing raceway by approximately half compared with a conventional type (68 series), thus successfully reducing the thickness of the bearing outer diameter to 90% of its former size.

In addition, we used a new manufacturing method to increase the number of rolling elements held, and increased the ball packing factor by approximately 50%, dynamic load rating by 10%, and static load rating by 30% compared with a conventional type (68 series), thus achieving 1.3 times higher capacity (long life).

We are going to start mass production at DAIBEA CO., LTD (JTEKT group company) and make proposals to various industrial machine manufacturers.

3.Sales Plan

| [Sales target] | 500 million yen/year (as of 2021) |

| [Sales destination] | Industrial machine manufacturers in Japan and overseas |

4.Production Plant

DAIBEA CO., LTD (JTEKT group company)