Development of ultra-small tapered roller bearing

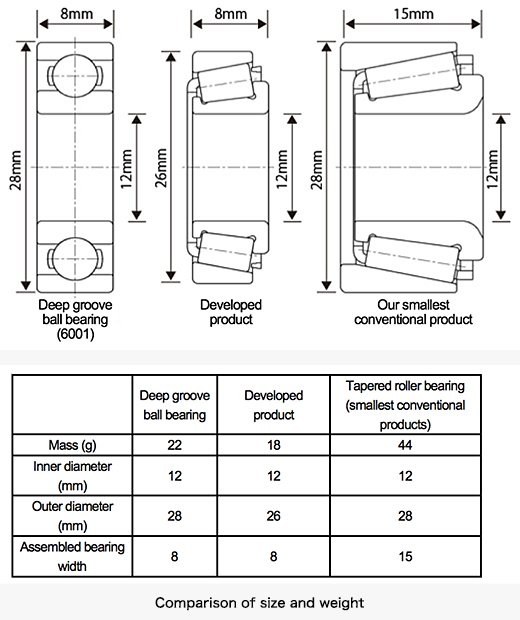

JTEKT Corporation (hereinafter JTEKT) has developed an “ultra-small tapered roller bearing” used in a wide range of industrial machines. For this developed product, we have achieved significant size and weight reduction (26 mm for outer diameter, 8 mm for assembled bearing width, and 18 g for mass) compared with our smallest conventional product, which contribute to performance improvement and size reduction of industrial machine products.

Photo of developed bearing

Photo of developed bearing

1.Background of development

Tapered roller bearings are used in a variety of industrial machines for its high load capacity and high rigidity.

Along with a growing demand for size reduction of industrial machine in recent years, tapered roller bearings are also required to be smaller. However, the size reduction of the tapered roller bearings is hindered by problems such as “difficulty in automatic conveyance due to the weight reduction of components” or “increase in difficulty of raceway polishing due to a narrower width”.

Therefore, for products which require a smaller size than conventional products, other types of bearing such as deep groove ball bearing had to be adopted, which restricted performance in some cases.

In developing this new product, we undamentally reviewed the production process including the conveyance method and developed a dedicated tool for raceway polishing, thus achieving the size reduction of tapered roller bearings. In addition, application of a resin cage narrowed the width by 50% and reduced the mass by 60% while keeping the rigidity equivalent to conventional products, which made an extreme size reduction possible.

2.Features of this developed product

(1) Comparison with a tapered roller bearing (smallest conventional product)

| Size | : Width narrowed by approximately 50% |

| Mass | : Reduced by approximately 60% |

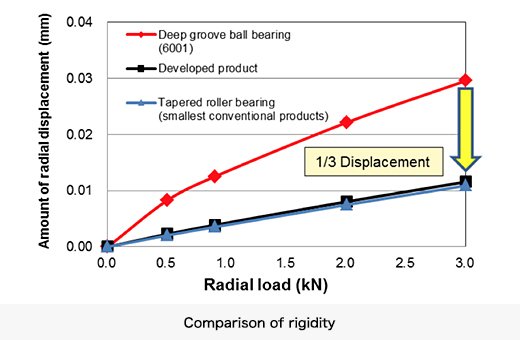

| Rigidity | : Equivalent level (Normally, size reduction leads to decrease in rigidity) |

(2) Comparison with a deep groove ball bearing (of equivalent size)

| Mass | : Reduced by approximately 15% |

| Rigidity | : Approximately 3 times |

3.Sales plan

| [Start of volume production] | Year 2018 |

| [Sales target] | 240 thousand pcs/year |

| [Sales destination] | Industrial machine manufacturers in Japan and overseas (such as robot and reduction gear manufacturers) |

4.Production plant

Kagawa Plant

JTEKT, under the tag-line “Key of your operation” of the bearing business brand “Koyo”, contributes to various industries as a partner who solves problems together with and provides happiness to customers.