TOYOTA's new "Land Cruiser" has been launched and equipped with JTEKT's TORSEN® LSD and Hub Unit

-Japan's first adoption of 3rd Generation Tapered Roller Bearing Hub Unit-

"TORSEN® LSD Type-B", "TORSEN® LSD Type-C" and "3rd Generation Tapered Roller Bearing Hub Unit" of JTEKT Corporation (hereinafter, JTEKT) are installed in the new "Land Cruiser" of Toyota Motor Corporation.

|

|

|

※TORSEN is a registered trademark of JTEKT.

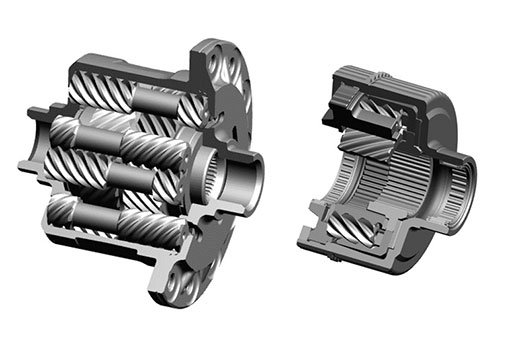

About TORSEN ® LSD

The LSD (Limited Slip Differential) is a drive device which optimally distributes the torque of the right and left wheels or the front and rear wheels when the vehicle turns.

The TORSEN (Torque-sensitive Limited-slip Differential) which is a type of LSD, optimally distributes driving force from the engine to each of the four wheels using a special gear mechanism.

Boasting high torque distribution performance and high durability, TORSEN is one of JTEKT's No. 1 & Only One products.

|

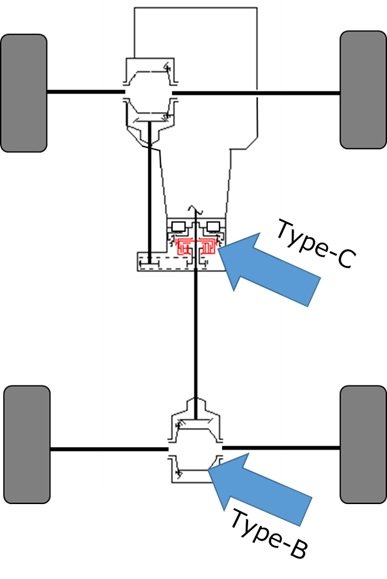

<TORSEN installation position> |

<TORSEN® LSD Type-B> TORSEN® LSD Type-B is equipped in front-wheel drive vehicles as well as rear-wheel drive vehicles to distribute torque to the right and left wheels. This development product has achieved durability by optimizing the lubrication holes. <TORSEN® LSD Type-C> TORSEN® LSD Type-C is equipped in the center differential of a four-wheel drive vehicle to distribute torque to the front and rear wheels. This development product is smaller and lighter than before. |

About the Hub Unit

The Hub Units are parts used for wheel parts that connect the vehicle and the tires, and they are support the weight of the vehicle while driving and also work to rotate tires smoothly while receiving external loads.

Of the above three products which are installed in the new Land Cruiser, the "3rd Generation Tapered Roller Bearing Hub Unit" is adopted and mass-produced for the first time in Japan.

-The features of the "3rd Generation Tapered Roller Bearing Hub Unit" are as follows. -

1.Background of the development

The main stream of the Hub Unit for vehicles adopts the Double Row Angular Ball Bearing.

However, large SUVs and commercial vehicles are heavier than passenger cars and require a longer life for the Hub Unit, so Hub Units that applies tapered roller bearings with a large load capacity are used.

In recent years, in order to achieve carbon neutrality, it is required to reduce energy loss more than ever in the environment surrounding the manufacturing industry including the automobile industry.

Under such circumstances, weight reduction, miniaturization, and torque reduction of the Hub Units that support the wheels of automobiles are indispensable technology because they are directly linked to fuel efficiency.

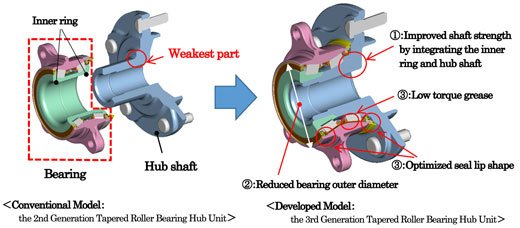

Then, by improving the Tapered Roller Bearing Hub Unit from 2nd Generation to 3rd Generation, we have achieved a reduction in environmental load.

2.Features of the New Product

JTEKT Hub Unit have evolved from the conventional 1st-Generation design to current advanced 3rd-Generation configuration by integration of flanges that facilitate their installation to vehicles.

This time, from the 2nd Generation Tapered Roller Bearing Hub Unit, in which the bearing and hub shaft were separated, we have realized the 3rd generation that integrates them. As a result, we have achieved weight reduction and miniaturization compared to conventional products, contributing to improved vehicle fuel efficiency.

<Contribution to improved fuel economy>

①Weight saving・・・

By integrating the inner ring and hub shaft, we improved the shaft strength and the assembly could be reduced in weight by 11% compared to the conventional model.

②Miniaturization・・・

By evolving the Hub Unit to the 3rd-Generation, the outer diameter of the bearing could be reduced, and as a result, the outer diameter of the spigot joint could be reduced by 5% compared to the conventional model.

③Achieved torque reduction・・・

We have achieved a 16% (*) reduction in friction torque by optimizing low torque grease and seal lip shape.

* Effect comparing the case of using conventional grease and seal lip with the case of using the developed products

<Contribution to improving workability>

By delivering assembly, we were able to reduce the assembly man-hours at the customer's site and contribute to improving workability.

<Contribution to comfortable driving>

By evolving the Hub Unit to the 3rd-Generation, it is possible to prevent the vehicle body vibration that occurs when the brake is stepped on and the phenomenon that the brake pedal vibrates back and forth. As a result, flange runout accuracy and quietness are improved, which contribute to comfortable driving.

3.Targets of SDGs that can contribute through this new product

Going forward, we will expand sales of this new Hub Units aimed at large SUVs and commercial vehicles, and contribute to the realization of a low-carbon society.

4.Sales and Manufacturing plan

| Sales target | 12 billion yen / year (in 2030) |

|---|---|

| Sales destination | Automotive manufacturers |

| Manufacturing plant | Shikoku Plant (Kagawa Pref.) and KOYO BEARINGS NORTH AMERICA LLC Richland Plant |