Development of Low Friction Torque Hub Unit improving Cold Robustness

~Applying a low torque seal that demonstrates high sealing performance even in extremely cold regions~

JTEKT Corporation has developed a Hub Unit that applies a seal with reduced friction torque that exhibits high sealing performance even in extremely cold regions.

Through this product, we will contribute to the realization of a low-carbon society not only in Japan but also in the global market including extremely cold regions.

1. Background of the development

In recent years, in order to achieve carbon neutrality, it is required to reduce energy loss more than ever in the environment surrounding the manufacturing industry including the automobile industry. Under such circumstances, reducing the friction torque of the Hub Unit that supports the wheels of an automobile is an indispensable technology because it is directly linked to fuel efficiency.

On the other hand, nitrile rubber used in the sealing part, which accounts for about half of the friction torque generated in the Hub Unit, is used as a sealing material not only in the Hub Unit but also in various fields. However, since cold robustness and rubber physical characteristics (strength / heat resistance / wear resistance) are contradictory matters, it has been an issue to achieve both cold resistance and low friction torque. In addition, nitrile rubbers generally have excellent oil resistance, wear resistance, and tear strength, but are inferior to other rubbers in cold resistance.

As the market is becoming more globalized, assuming that our Hub Units will be used in harsher environments than before, expanding the operational temperature range of sealing rubber has become an important issue.

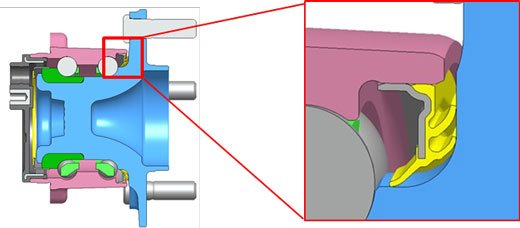

【Figure 1. Location of rubber for sealing (developed product)】

【Figure 1. Location of rubber for sealing (developed product)】

2. Features of the New Product

① Achieved torque reduction・・・

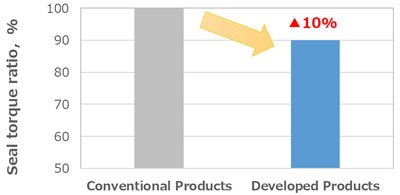

By applying the rubber material developed this time for the seal, we have achieved -10% reduction in seal torque.

② High sealing performance・・・

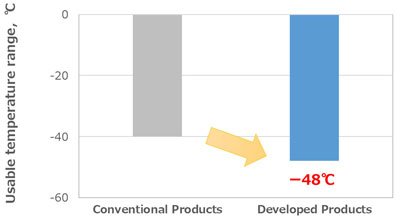

Since the rubber does not lose its elasticity even in an extremely cold environment of -40℃ or less, the sealability can be maintained. This prevents muddy water from entering the Hub Unit even in extremely cold regions such as North America and Russia.

【Figure 2. The results of seal torque evaluation】

【Figure 2. The results of seal torque evaluation】

【Figure 3. The results of operational temperature of rubber material】

【Figure 3. The results of operational temperature of rubber material】

3. Targets of SDGs that can contribute through this new product

The rubber material developed this time can be used not only in Hub Units but also in various industries including other automobile parts, and will contribute to the realization of a low-carbon society.

4. Sales and Manufacturing plan

| Sales target | 2.5 billion yen/year (2025) |

|---|---|

| Sales destination | Automotive manufacturers, Manufacturers in the industrial machinery field, etc. |

| Manufacturing plant | Kameyama Plant and Shikoku Plant |