Development of "JTEKT Ultra Compact Diff." for eDrive system

~ Contribute for further eAxle compactness and higher power density ~

In response to the strong expansion of battery electric vehicle (BEV) market, JTEKT has developed "JTEKT Ultra Compact Diff. (hereafter referred to as JUCD)", as differential for BEV eAxle. JUCD is extremely small compared with traditional differential for the same strength.

*JTEKT Ultra Compact Diff. and JUCD are registered trademarks of JTEKT.

Needs for eAxle compactness

Following with automotive electrification growth trend, development and production of eAxle, which integrate inverter, motor, and reducer including differential, is growing rapidly worldwide. In order to develop a better BEV, the eAxle, which is the heart of eDrive system, is required to be smaller and should have higher power density in future.

In response to this market need, demand of very compact differential for eAxle is expected to grow, and will replace the bevel gear differential widely used for traditional vehicles.

JUCD Background

JTEKT has developed a very compact size and highly durable differential as "JTEKT Ultra Compact Diff.", which is suitable for BEV eAxle. A differential is a device that absorbs the rotational speed difference between the left and right wheels that occurs in cornering, and transfer the torque between drive power source to both wheels.

We have further evolved the Torsen LSD technology, which is a high-performance differential suitable for high power 4WD / sports vehicles, by adding new knowledge of gear design and machining technologies. Introducing smaller gear module geometry into the unique composite planet gear set, we have made it smaller in radial and axial directions, and reborn as "JUCD" general-purpose product for eAxles.

*LSD:Limited Slip Differential

|

|

|

| 【JTEKT Ultra Compact Diff.】 | 【JUCD gear structure】 | 【Bevel gear type differential example】 |

JUCD Features and Advantages

1. High torque density and durability. Wide range of torque capacity.

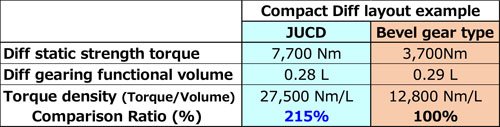

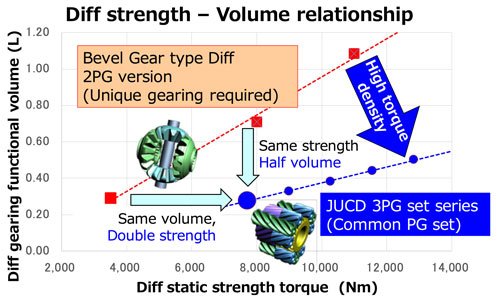

Compared to the bevel gear type differential, the JUCD has increased differential gear mesh width and the number of meshes with the output gears. As a result, if the differential gearing functional volume is the same, the differential strength is more than doubled, and if the differential strength is the same, the required volume is less than half.

In addition, high durability is ensured by reducing each load of the sliding surfaces between pinion gears to differential case or drive pin, compared to the bevel gear type differential.

JUCD can support wide range of torque capacity requirement, by selecting the number of output gear teeth and the size of outer diameter and/or additional planet gear set, while keeping the common planet gear sets.

With these, JTEKT can now propose the optimum ultra compact differential for various eAxle reducer structures and torque requirements.

JUCD contributes to the further eAxle compactness and higher power density, and also improves flexibility of the eAxle mountability to the vehicle.

【Comparison of torque density between JUCD and bevel gear type】

【Comparison of torque density between JUCD and bevel gear type】

【Comparison of volume and strength between each differential series】

【Comparison of volume and strength between each differential series】

2. Improve electricity power consumption and safety performance

JUCD also has mild torque biasing LSD characteristics derived from its unique structure. This feature contributes to reducing the friction brake load that intervenes when the tire slips at vehicle start on slippery road surface or climbing a hill. It also contributes to expand the range of regenerative braking situations by stabilizing vehicle behavior during deceleration.

These effects are expected to improve electricity power consumption.

In addition, this characteristics also contribute to improve straight-line stability, which will reduce continuous steering wheel angle adjustment during steady straight-line driving, contributing to reduce driver's fatigue and improve ride comfort.

Targets of SDGs that can contribute through this new product

7.3 By 2030, double the global rate of improvement in energy efficiency

9.4 By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities

Prospect

JTEKT group opened the "Gear Innovation Center" in November 2021, and as a comprehensive gear builder, we have established a system to propose high-performance gears that meet customer needs in an extremely short period of time.

By combining the analysis technology with manufacturing cultivated in automotive parts, bearings, and machine tools, we have established our own 3D tooth surface modification machining technologies, and we propose compact, highly durable, low-noise, high-performance gears and reducers.

JTEKT pursues the synergistic effects of reduction gears, bearings, and gear processing technology, and strengthens the competitiveness of gear modules. We will contribute to the realization of a low-carbon society.