JTEKT's newly developed "ITCC® for FR-based 4WD vehicles" and "Lightweight and Compact Motorized Rake Tilt & Telescopic Steering Column" are installed in Mazda CX-60.

JTEKT CORPORATION has developed a new "ITCC (Intelligent Torque Controlled Coupling) for FR-based 4WD vehicles" and has jointly developed a "Lightweight and Compact Motorized Rake Tilt & Telescopic Steering Column" with Fuji Kiko Co., Ltd which one of the JTEKT group companies.

The above two products have been adopted in Mazda Motor Corporation's new crossover SUV "MAZDA CX-60". Furthermore, the ITCC developed this time received the "Development Technology Excellence Award" from Mazda. The Steering Column contributes to "Driver Personalization System," which recognizes the driver and adjusts the steering wheel to the optimum driving position.

ITCC is a registered trademark of JTEKT Corporation.

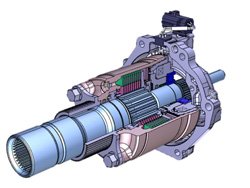

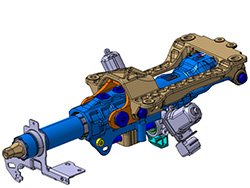

|

|

| 【Left: ITCC (Intelligent Torque Controlled Coupling) for FR-based 4WD vehicles, Right: Lightweight and Compact Motorized Rake Tilt & Telescopic Steering Column】 |

|

<MAZDA CX-60>

<MAZDA CX-60>

1. ITCC for FR-based 4WD vehicles

The ITCC is an electronically controlled system that continuously changes and transmits driving force to the front and rear wheels in response to road conditions and vehicle speed. With this mechanism, the product contributes to both excellent vehicle dynamics and improving fuel efficiency.

JTEKT has developed a new ITCC for FR-based 4WD vehicles to respond to driving concept advocated by Mazda, Jinba Ittai, a term meaning rider and horse as one.

■ Features of the New Product

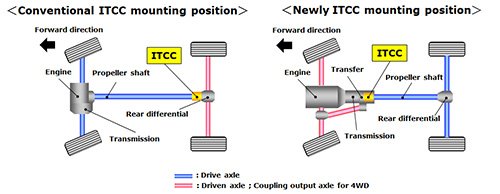

【Comparison of ITCC mounting position between

conventional and developed products】

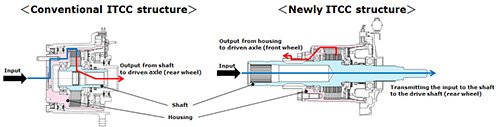

【Comparison of ITCC structure between

conventional and developed products】

(1) Optimization of ITCC structure for FR-based 4WD vehicle layout and reduction of weight and size

The structure of the ITCC, which was designed to be installed in conventional FF-based vehicles, has been replaced with a through-shaft structure that directly connects the transmission and rear propeller shaft, enabling be installed in FR-based vehicles.

Furthermore, the smaller diameter of the housing, which matches the layout inside the transfer, saves space and reduces weight by approximately 10% compared to conventional models. This contributes to improving fuel efficiency.

(2) Higher accuracy of front/rear wheels torque distribution

The temperature sensor enables current control in response to temperature changes in the transfer that occur during driving and contributes to improving torque accuracy.

In addition, a clutch with friction material having excellent fuel efficiency and durability has been adopted in the ITCC unit. These features enable both improved fuel efficiency and driving performance with 4WD.

2. Lightweight and Compact Motorized Rake Tilt & Telescopic Steering Column

The steering column is the shaft part that supports the steering wheel, and it is a product that transmits the force of turning the steering wheel to the front wheels.

Among them, the Motorized Rake Tilt & Telescopic Steering Column allows the steering wheel position to be adjusted up and down (tilt) and back and forth (telescopic) with a single switch so that the driver can drive comfortably.

This time, in order to respond to market needs such as improving fuel efficiency and securing space below the knees, we developed the concept of "lightweight and compact".

【Steering column mounting position】

【Steering column mounting position】

■ Features of the New Product

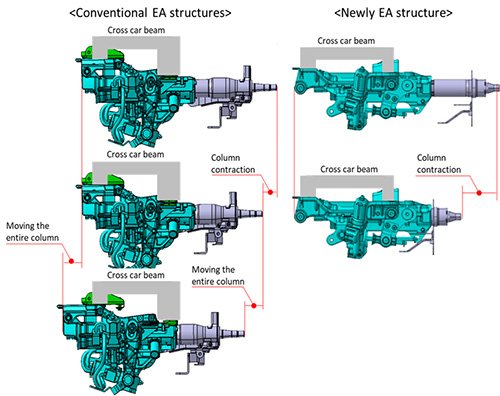

(1) Weight reduction by simplifying the EA (Energy Absorption) structure

The steering column has an EA structure to absorb the shock on the driver and reduce injury in the event of an accident.

Conventional EA structures require moving the entire column forward in the vehicle and contracting the contractible two-body tube portion of the column. On the other hand, with the newly developed product, the EA structure could be completed only by column contraction. This has resulted in a reduction in the number of parts and a 30% reduction in the overall column mass compared to the conventional product.

In addition, the optimization of part geometry by reducing the wall thickness of aluminum parts and hollowing the shaft has resulted in both high rigidity and light weight.

【Comparison of EA structure between

【Comparison of EA structure between

conventional product and developed product】

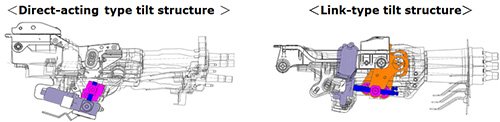

(2) Compact tilt structure

The tilt structure for moving the handle in the vertical direction has been changed from the conventional direct-acting type, in which the motor is located on the lower side of the column, to a link type.

In the direct-acting type, the handle is moved up and down by moving the nut up and down with the screw rotated by the motor. In other words, the screw was placed above and below the nut, and the motor was placed below the screw, so the structure was such that parts piled up in the space below the column.

On the other hand, the use of a link-type tilt structure eliminates the need to place a nut directly under the column. This reduces the column lower height dimension by 30% compared to the direct-acting type, thus saving space.

The space under the column also contributes to improved knee safety in the event of a secondary collision.

【Comparison of tilt structures】

【Comparison of tilt structures】

3. Targets of SDGs that can contribute through those new products

【7.3】 By 2030, double the global rate of improvement in energy efficiency

9.4】 By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities

【12.5】By 2030, substantially reduce waste generation through prevention, reduction, recycling and reuse

JTEKT will continue to contribute to the realization of a low-carbon society through manufacturing that is "for the Earth, for Society and for our Customers."