Development of "JTEKT Ultra Compact BearingTM"

Contribute for further eAxle compactness

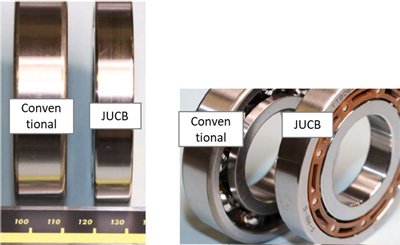

In response to the strong expansion of battery electric vehicle (BEV) market, JTEKT has developed "JTEKT Ultra Compact Bearing. (here after referred to as JUCB)", as ball bearing for BEV eAxle. JUCB is extremely small compared with conventional bearing for the same diameter.

JUCB Back ground

Following with automotive electrification growth trend, development and production of eAxle, which integrate inverter, motor, and reducer including differential, is growing rapidly worldwide. In order to develop BEV, the eAxle, which is the heart of eDrive system, is required to be smaller and should have higher power density in future.

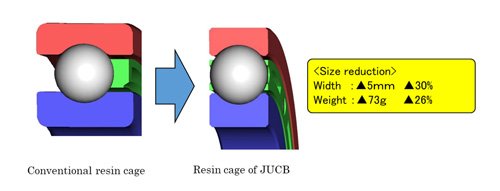

In 2016, JTEKT developed a high-rigidity combination resin cage bearing, which is mainly used for HEV and BEV motors. JUCB has realized a narrowing of the width of the bearing by providing a hole in the side of the high-rigidity combination resin cage and making the cage as small as possible. In addition, the strength of the cage was ensured even in the midst of narrowing, by establishing a unique mold design and molding method.

JUCB Features and Advantages

●Shortened unit length, while maintaining the strength and durability of bearings

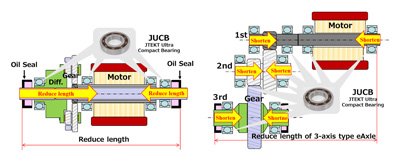

The bearing performance such as strength and durability is the same as that of conventional products, and the bearing width has been narrowed to the limit. By applying it to the general-purpose size "6207", the axial dimension is shortened by 5 mm (about 30%) and the weight is reduced by 73 g (about 26%).As a result, JUCB has made it possible to shorten the unit length of coaxial eAxle and 3-axis eAxle.

【Unit length shortened by JUCB of coaxial type (left) and 3-axis type (right) eAxle】

【Unit length shortened by JUCB of coaxial type (left) and 3-axis type (right) eAxle】

Sales Target

7 billion Yen/Year

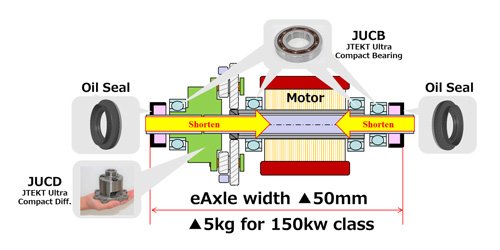

The synergy of the JTEKT Group realize miniaturization and weight reduction of eAxle

Futuremore, in addition to JUCB, we will create synergies of the JTEKT Group in combination with JUCD and Oil Seal propose technologies that contribute to electrification to customers.

When the above three products are applied to a 150 Kw coaxial eAxle, it is calculated that the unit length of the eAxle is reduced by approximately 50 mm and the weight is reduced by approximately 5 kg. In addition to shortening the width dimensions of the eAxle, it is expected to contribute to shortening the front and rear dimensions and height dimensions, and the accompanying miniaturization and weight reduction.

JTEKT Group will continue to contribute to the further miniaturization and weight reduction of the eAxle. In addition to improving the BEV cruising range by increasing the battery capacity, we will contribute to the improvement of BEV functions such as increasing the flexibility of the eAxle mounting position, securing the vehicle and luggage space, increasing the flexibility of the vehicle silhouette, and improving the electric power consumption.

【Downsizing and weight reduction of coaxial type eAxle by JTEKT Group's technology】

【Downsizing and weight reduction of coaxial type eAxle by JTEKT Group's technology】

Prospect

JUCB is applicable not only to BEV eAxles, but also to industrial machinery such as construction machinery, agricultural machinery, robots, and drones. We will meet the needs for miniaturization of all types of drive systems.

JTEKT will continue to overcome business barriers and work together as a group to further strengthen technologies that contribute to electrification. We will contribute to the realization of a low-carbon society through activities that are "for the earth, for society, and for customers."

Reference

Press release on 26, Sep, 2016

Development of high speed rotation deep groove ball bearings

https://www.jtekt.co.jp/e/news/160926.html

Press release on 31, Aug, 2022

Development of "JTEKT Ultra Compact Diff." for eDrive system

https://www.jtekt.co.jp/e/news/2022/220831.html

Targets of SDGs that can contribute through this new product

7.3 By 2030, double the global rate of improvement in energy efficiency

9.4 By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities