Development of "JTEKT Ultra Compact SealTM"

Contribute for further eAxle compactness

In response to the strong expansion of battery electric vehicle (BEV) market, JTEKT and its group company Koyo sealing techno has developed "JTEKT Ultra Compact Seal. (here after referred to as JUCS)", as compact diff. side oil seal for BEV eAxle.

A differential side seal is an oil seal that is attached to the connection between the differential (hereinafter referred to as "differential") and the drive shaft, and it works to prevent oil leakage from the inside and contamination from the outside.

A differential gear is a device that absorbs the rotational difference between the left and right wheels that occurs when a car turns, and transmits torque.

JUCS Background

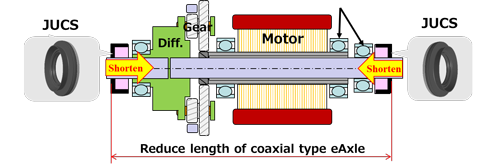

Following with automotive electrification growth trend, development and production of eAxle, which integrate inverter, motor, and reducer including differential, is growing rapidly worldwide. In order to develop BEV, the eAxle, which is the heart of eDrive system, is required to be smaller and should have higher power density in future.

Under these circumstances, the JTEKT Group has succeeded in reducing the width of the differential side seal by developing a rubber material and reviewing the lip design.

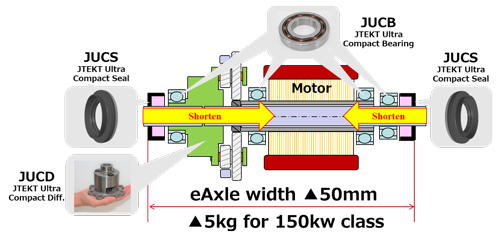

【JUCS mounting position on coaxial type eAxle】

JUCS Features and Advantages

1: Unit length can be shortened while maintaining followability at low temperatures

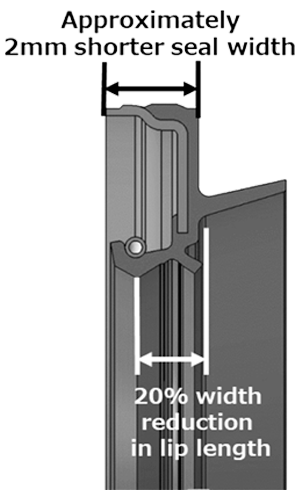

At low temperatures such as below zero, the rubber of the differential side seal hardens, reducing the ability of the seal lip to follow shaft eccentricity and increasing the possibility of oil leakage from the eAxle.In response to this, we have developed a rubber material with 1.2 times the low-temperature resistance of conventional materials. In addition, by optimizing the rubber and spring, we have improved the ability to follow the eccentricity at low temperatures.

As a result, it has become possible to shorten the lip length of the inner circumference of the seal by 20% while maintaining the same eccentricity followability as before.In addition, the outer periphery of the seal has a structure in which the metal ring and the housing are in contact with each other, maintaining the seal retention force that decreases due to the reduction in width.

2: Approximately 4mm reduction in eAxle width

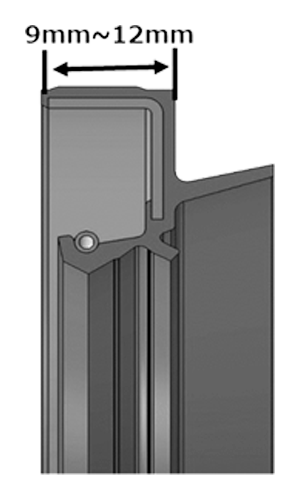

With the size mainly used for differential side seals, which has an outer diameter of 50 to 80 mm and a width of 9 to 12 mm, it is possible to shorten the seal width by approximately 4 mm on both sides, contributing to shortening the eAxle unit length.

【Shape of conventional product】 【Shape of conventional product】 |

【Shape of JUCS】 【Shape of JUCS】 |

Sales Target

500 million Yen/Year

The synergy of the JTEKT Group realize miniaturization and weight reduction of eAxle

Furthermore, in addition to JUCS, we will create synergies of the JTEKT Group in combination with JUCD and JUCB propose technologies that contribute to electrification to customers.

When the above three products are applied to a 150 Kw coaxial eAxle, it is calculated that the unit length of the eAxle is reduced by approximately 50 mm and the weight is reduced by approximately 5 kg. In addition to shortening the width dimensions of the eAxle, it is expected to contribute to shortening the front and rear dimensions and height dimensions, and the accompanying miniaturization and weight reduction.

JTEKT Group will continue to contribute to the further miniaturization and weight reduction of the eAxle. In addition to improving the BEV cruising range by increasing the battery capacity, we will contribute to the improvement of BEV functions such as increasing the flexibility of the eAxle mounting position, securing the vehicle and luggage space, increasing the flexibility of the vehicle silhouette, and improving the electric power consumption.

【Downsizing and weight reduction of coaxial type eAxle by JTEKT Group's technology】

Prospect

JUCS is applicable not only to BEV eAxles, but also to industrial machinery such as construction machinery, agricultural machinery, robots, and drones. We will meet the needs for miniaturization of all types of drive systems.

JTEKT will continue to overcome business barriers and work together as a group to further strengthen technologies that contribute to electrification. We will contribute to the realization of a low-carbon society through activities that are "for the earth, for society, and for customers."

Reference

Press release on 31, Aug, 2022

Development of "JTEKT Ultra Compact Diff." for eDrive system

https://www.jtekt.co.jp/e/news/2022/220831.html

Press release on 18, Oct, 2022

Development of "JTEKT Ultra Compact BearingTM"

https://www.jtekt.co.jp/news/2022/221018_1.html

Targets of SDGs that can contribute through this new product

7.3 By 2030, double the global rate of improvement in energy efficiency

9.4 By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities