Development of "JTEKT Ultra Earth BearingTM"

Contribute to enhancing reliability and further downsizing of eAxle

In response to the strong expansion of battery electric vehicle (BEV) market in the future, JTEKT has developed "JTEKT Ultra Earth BearingTM (hereinafter referred to as "JUEB")" jointly with Koyo Sealing Techno Co., Ltd. (renamed JTEKT Sealing Techno Corporation on April 01, 2023), one of the JTEKT group companies.

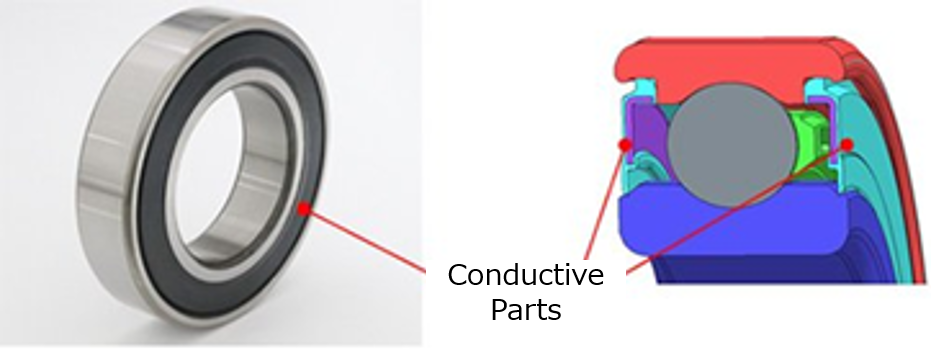

JUEB is a conductive ball bearing for eAxle motors with a function of conductivity.

Background of JUEB Development

Following with automotive electrification growth trend, development and adoption of an electric drive system called eAxle, which integrates an inverter, motor, and reducer including a differential, are expanding rapidly.

In order to develop better BEVs such as those with lower power consumption, longer range, etc., enhancement of reliability and downsizing are required of eAxle, which is the heart of the drive source.

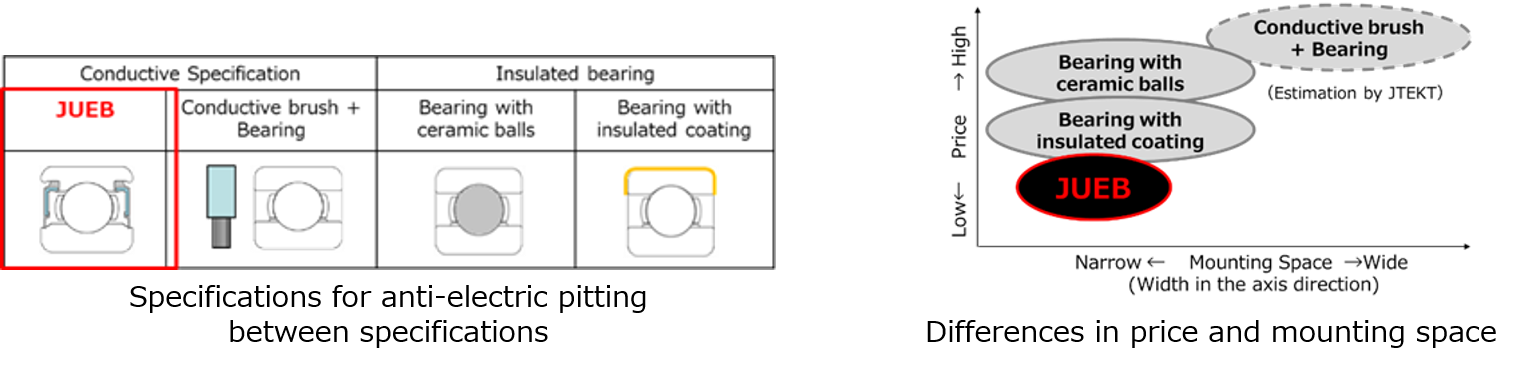

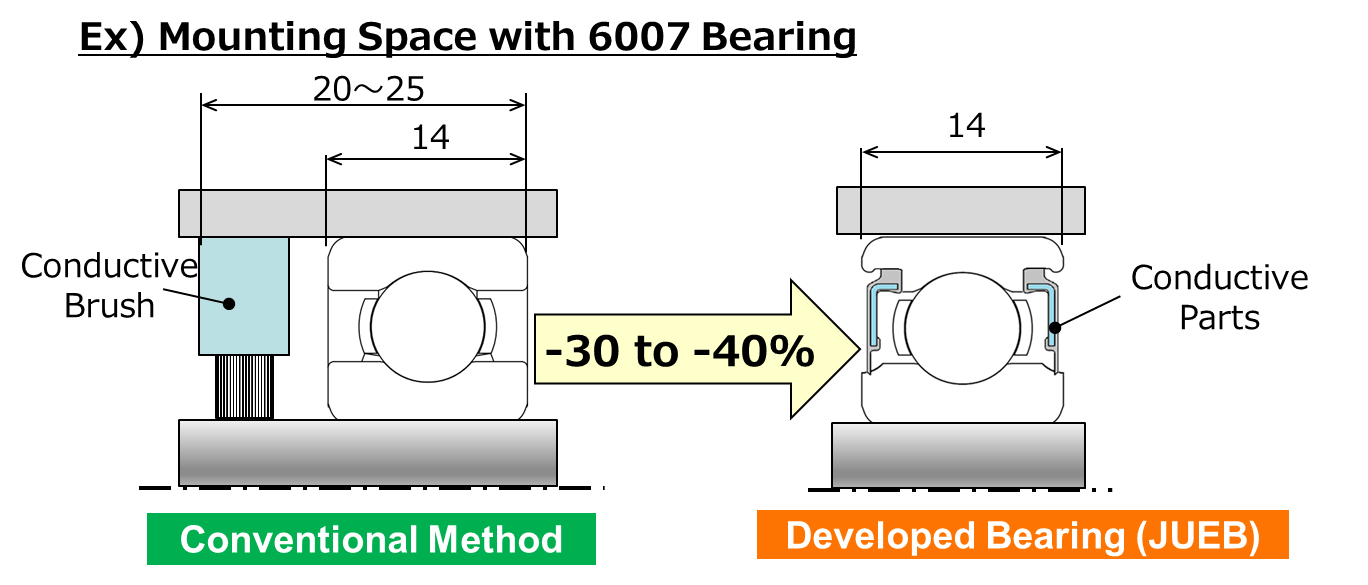

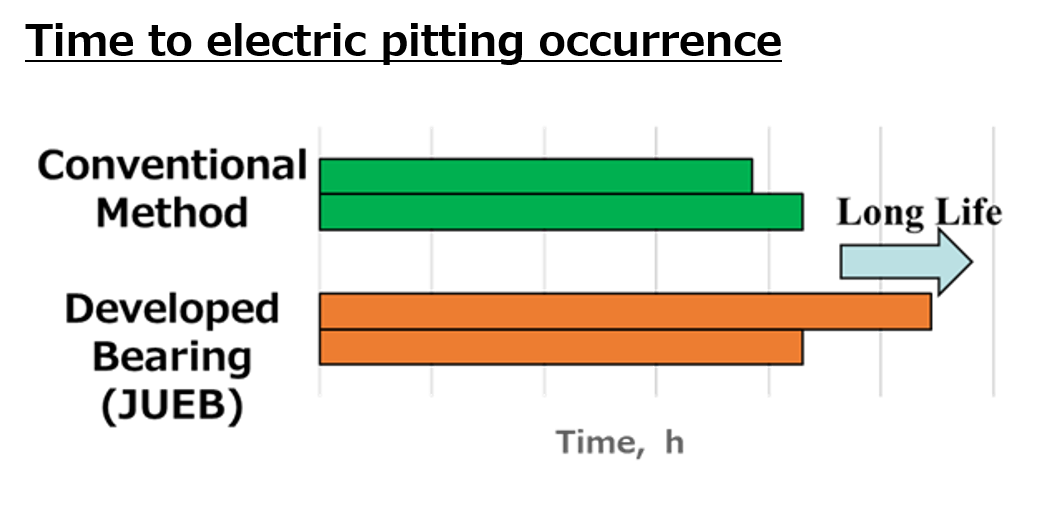

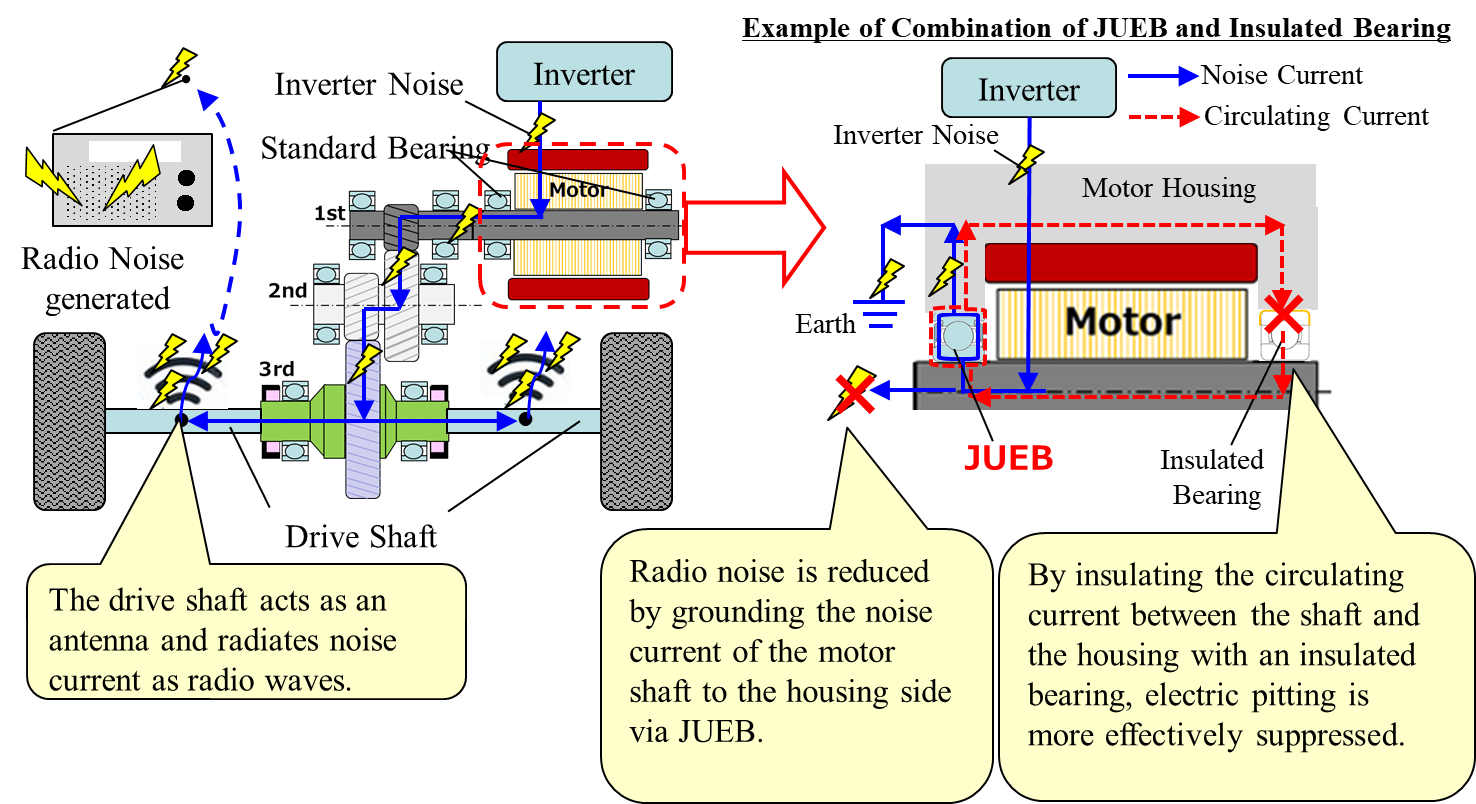

Bearings for motors driven using inverters have had an issue of damage called electric pitting due to the flow of electricity inside the bearings. If electric pitting occurs in the bearing, it affects the performance of the eAxle due to abnormal noise during rotation and reduced bearing life. As a countermeasure against electric pitting of bearings, conventional technology has taken measures to insulate the bearings, such as using ceramic balls as insulators and forming an insulating coating on the surface of the outer ring. However, these countermeasures have an issue that the cost is very high. In addition, countermeasures against electric pitting other than improving a bearing itself have been put into practical use. One example is the conductive parts called conductive brushes (earth brushes) and earth rings, but these have problems of larger mounting space, time/labor for assembly, and cost increase. In 2020, JTEKT developed an insulating coating bearing that is less expensive than conventional technology as a countermeasure against electric pitting. JUEB, developed this time, has achieved a lower price and smaller size than a bearing with a conductive brush as well as a lower price than an insulated bearing by using newly developed built-in conductive parts inside the bearing.

JUEB Features and Advantages

(1) Size reduction with equivalent electric pitting resistance

It is confirmed that the electric pitting resistance is equal to or higher than that of a conventional bearing with a conductive brush on the market.

By employing built-in conductive parts for the bearing without changing bearing dimensions, the mounting space for the separate conductive brush beside the bearing is not necessary any more, and the motor shaft can be shortened accordingly.

(2) More effective electric pitting countermeasures

By using the already developed insulated bearings and JUEB depending on the application, it will be possible to suppress electric pitting more effectively. In addition, by electrically connecting the housing and shaft of the motor with JUEB effects on countering radio noise caused by inverter noise can be expected.

(3) Improve power consumption and extend range by downsizing the eAxle

JUEB downsizes the eAxle by shortening the shaft length and reducing the weight, which facilitates securing the mounting space of batteries, increases the flexibility of tire position, etc. JUEB can thus improves the mountability of other BEV parts.

As a result, it contributes to the improvement of BEV power consumption and the extension of range.

Sales Target

600 million Yen/Year (2030)

Prospect

Electrification is expanding not only to automobiles, but also to industrial machinery such as construction equipment, agricultural equipment, and drones. Under such circumstances, we will propose JUEB to BEV and eAxle makers first. We, however, would like to meet the needs for anti-electric pitting for all types of bearings on electric drive units in every industry inside and outside Japan in the future.

JTEKT will continue to reinforce the competitiveness of technologies for bearing development. We will contribute to the realization of a low-carbon society through activities that are "for the earth, for society, and for customers".

Reference

Press release on 23, Jun, 2020

JTEKT develops Electric Pitting Prevention Bearing for EV Motor

https://www.jtekt.co.jp/e/news/2020/002690.html

Targets of SDGs that can contribute through this new product

7.3 By 2030, double the global rate of improvement in energy efficiency

9.4 By 2030, upgrade infrastructure and retrofit industries to make them sustainable, with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes, with all countries taking action in accordance with their respective capabilities