- Machine Tools

- Machining Centers

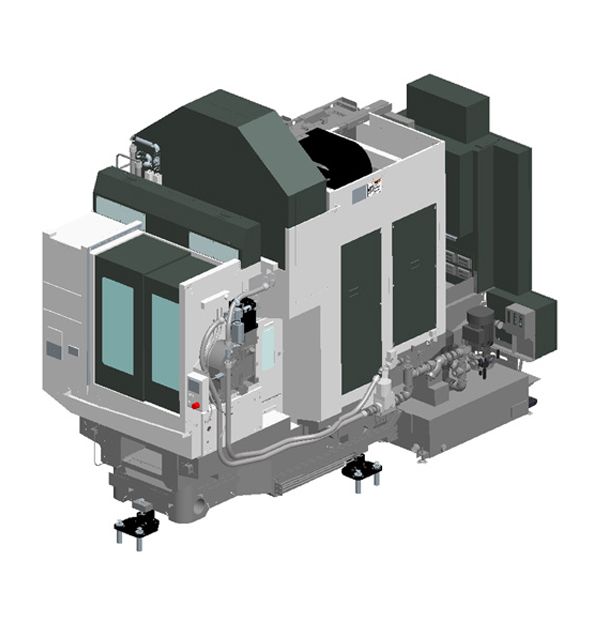

- Horizontal spindle machining center for line TH555i4

Horizontal spindle machining center for line TH555i4

Space saving horizontal machining center best for mass production.

Features . Outline

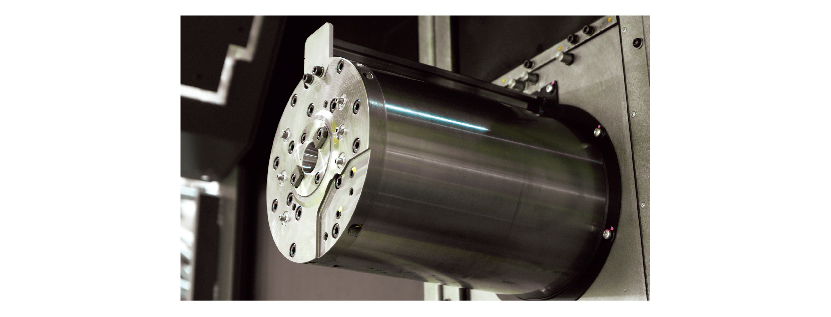

3-point guide of high rigidity Z axis allowing moving the z-axis in high speed, high acceleration and high accuracy.

The Z axis quill feed method has an advantage of drastic reduction in weight of traveling objects. On the other hand, this system has a problem of how to retain rigidity at the Z axis advance end. JTEKT has adopted the 3-point guide method of which 2 points are applied for the lower side and 1 point for the upper side. Both speed and rigidity are provided with this method. In addition, the quill has a round shape so that piling of chips at the quill upper part is prevented.

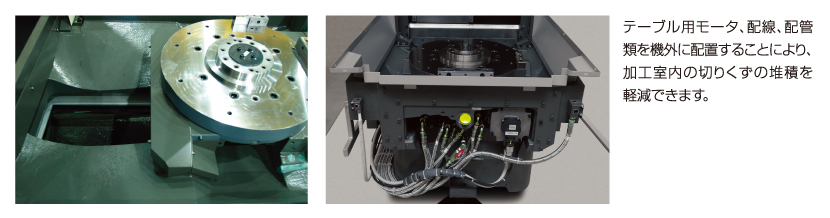

Reliability starts with chip disposal. The design of a center trough that makes it possible to deal with chip disposal directly beneath the cutting point.

Chip disposal plays a critical role in machine operation efficiency. A chip disposal port located in the center of the bed improves a chip disposal capacity. Furthermore, coolant consumption is substantially reduced, helping to make the equipment more environmentally friendly.

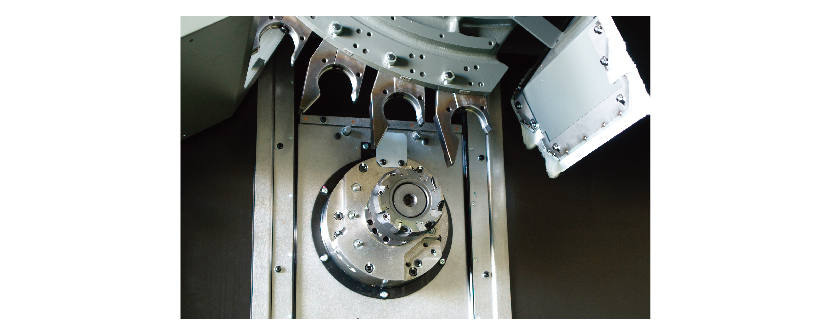

Direct magazine tool change method improving the reliability of tool change

JTEKT was the first in the industry to adopt the direct magazine method to improve reliability in tool change. Compared with the arm exchange method, JTEKT method requires no motors for turning the arm, reduction gears, guides or actuators for operating the magazine shutter, which allowed a drastic reduction in number of parts for the machine

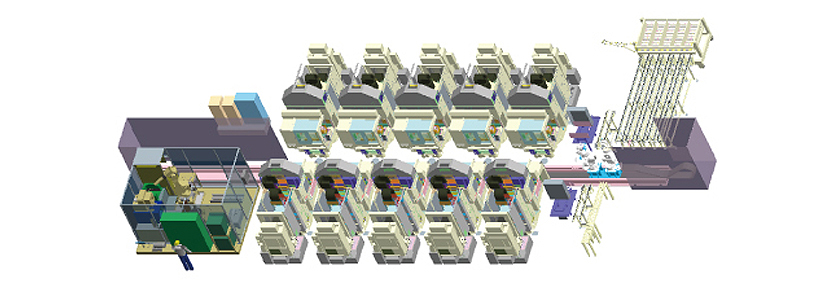

Example of a production line proposal

● Aluminum cylinder block production cell