- JTEKT TOP

- Sustainability

- Environmental Report

- Environmental Management

Environmental Management

Sustainable Development Goals (SDGs) were adopted in September 2015 at the UN Sustainable Development Summit. Of the 17 goals aimed to be achieved by 2030, many are related to the environment. A company's business activities affect the planet environment in various ways. Not only are companies required to comply with the environmental regulations of each country, but also set targets and policies autonomously and proactively, as well as promote initiatives for conserving the planet environment throughout all business activities. JTEKT promotes initiatives by positioning environmental management as one of the major issues for the sustainable development of the planet.

Environmental Action Plan 2025/FY2022 Activity Result

| Category | Initiative Items | Target and initiative policy | FY2022 Activity Result | Assessment |

|---|---|---|---|---|

| Environmental Management | (1) Reinforcement and promotion of consolidated environmental management | ①All affiliated companies develop and roll out environmental action plans based on the JTEKT Group Environmental Vision ②Establishing environmental management that considers social issues and stakeholder expectations |

|

◯ |

| (2) Promotion of environmental activities in collaboration with business partners | ① Promote green purchasing to all suppliers of parts and material • Control and reduce substances of concern contained in parts and materials • Request formulation and application of an environmental management system ② Promote purchase of environmentally considerate products |

|

||

| (3) Promotion of environmental education activities | ① Promote environmental awareness education that increases employees' environmental awareness ② Promote rank-based learning ③ Roll out JTEKT Environment Month (June) |

|

||

| Preservation and improvement of regional environment, Establishment of communication | (4) Thorough prevention of environmental issues and compliance with legal standards | ① Promote continued zero legal violations and resident complaints through reinforcement and improvement of daily management duties ② Thorough wastewater management based on self-established standards that are stricter than regulations |

|

|

| (5) Establishment of good relationships with local residents | ① Promote environmental conservation activities around plants ② Build good relationships with local residents and local government through community meetings |

|

||

| (6) Proactive disclosure of environmental information and enhancement of communication activities | ① Promote disclosure of the Environmental Report and establish better communication with government agencies and local residents ② Improve the JTEKT brand image and external evaluation through proactive disclosure of information |

|

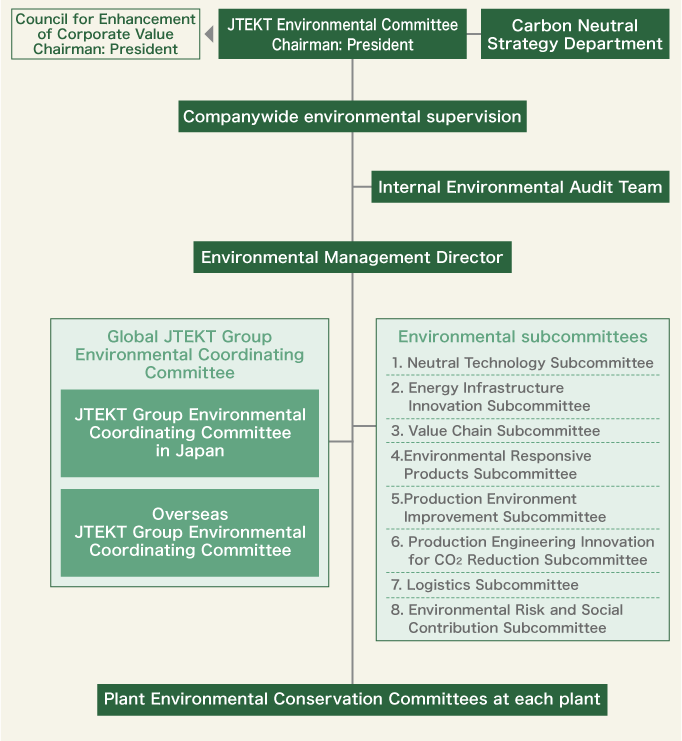

Promotion structure

JTEKT has established a structure to promote environmental management centered on the "JTEKT Environmental Committee", which is chaired by the president. The "JTEKT Environmental Committee" meets twice a year to set target values based on company policy, as well as to deliberate and determine measures and manage progress. The results of deliberations by the Committee are reported and deliberated at the "Council for Enhancement of Corporate Value", which is attended by all directors, including outside directors, and when budgetary measures are required for countermeasures, they are brought up for discussion to the the Senior Executive Officer Meeting or the Board of Directors, and following discussion by management,they are reflected in management strategies.

Furthermore, subcommittees of the "JTEKT Environmental Committee" have been established, where practical studies and assessments in various fields are conducted, addressing climate change including the reduction of Scope 3 emissions in energy conservation, resource recycling, production engineering innovation, energy infrastructure, logistics, technology and research, and value chains.

As for the system at plant level, each plant has Plant Environmental Conservation Committee chaired by the plant manager, which monitors CO2 emissions, waste emissions, water consumption, etc. at a committee meeting in the following month. JTEKT also has established the Global JTEKT Group Environmental Coordinating Committee to implement groupwide environmental initiatives. This committee reviews actions by individual domestic and overseas Group companies, discusses annual action plans, and exchanges information and opinions relating to environmental management. Furthermore, in 2021, JTEKT established the Carbon Neutral Strategy Department under the direct authority of the president, and it is facilitating communication among business divisions.

These initiatives are periodically reported to the "Council for Enhancement of Corporate Value", a company-wide registered meeting with members of the Board of Directors including outside directors, and are subject to oversight by the Council.

JTEKT Group Environmental Coordinating Committee in Japan

JTEKT's 17 domestic group companies share targets and promote group-wide activities to reduce CO2 emissions, reduce waste, and prevent environmental abnormalities. Environmental Coordinating Committee meetings for the group companies are held three times a year. At the meeting in April 2022, the environmental officers of domestic group companies gathered to remotely review each company's FY2021 environmental activities and planned activities for FY2022. In July 2022 and January 2023, the meetings were held by the environmental managers of each company to discuss the results of their activities and future efforts and to exchange opinions about the next Environmental Action Plan 2025, initiatives for achieving carbon neutrality, and improvement of each company's environmental management level.

My SDGs

"Carbon Neutrality Initiative"

Our company manufactures and sells automotive equipment, electric control equipment, FA control systems, and video information equipment. A lot of electric power (energy) is consumed in the design and manufacturing processes of each equipment. As the world calls for SDGs, the JTEKT group is also taking up concrete measures against climate change (i.e., carbon neutrality). The Environmental Committee at our company plays a central role in the promotion of carbon neutrality initiatives and works to develop energy-saving products and install solar power systems using power-saving devices and natural energy.

We will continue to work on CO2 reduction through energy-saving developments and expansion of solar power generation facilities.

Overseas JTEKT Group Environmental Coordinating Committee

Global Safety & Environment Conference

In June 2022, JTEKT held a web meeting with regional headquarters (North America, Europe, ASEAN, China, India, South America), to confirm our Medium-Term Management Plan in the environmental field, our initiative policies, and the status of our initiatives to achieve the total CO2 emissions target by 2030. And thus, we mutually confirmed that the JTEKT Group will unite to improve environmental performance and work together to achieve the "Environmental Action Plan 2025", which was formulated to realize the Environmental Challenge 2050.

Overseas Regional Environmental Meeting

The regional headquarters gathered regional business entities to hold remote regional environmental meetings. In 2022, the Safety and Health Meeting was held in China in December, the Safety and Health Environment Meeting was held in the United States in October. It has also been held as a regular monthly meeting since October 2020 in Europe and January 2023 in ASEAN (Thailand). The meetings are attended by the safety and environment manager of each region and regional corporation, and through reports about the environmental activities and issues of each local subsidiary and disclosure and sharing of improvement cases and JTEKT's initiatives, we endeavored to raise mutual awareness of environmental issues among the business entities.

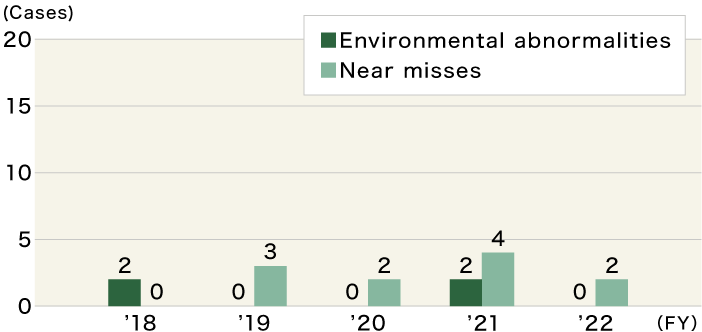

Environmental accident prevention activities

To prevent environmental incidents, JTEKT prepares an" Environment Risk Map" covering major management points and is utilizing this in our daily inspections, etc. Moreover, we also require both our domestic and overseas group companies to conduct daily management in accordance with the"environment risk map" as part of efforts to prevent environmental incidents. In order to comply with environmental legislation, treaties and convention levels, we have set internal standards (*) more stringently than each regulation requires.

*: JTEKT's internal standards for effluent and atmospheric discharge are below 80 percent of regulatory requirements.

Legal compliance with environmental legislation

- In FY2022, there were no environmental abnormalities occurred at JTEKT.

- There were no fines or charges related to Environmental accidents or complaints, nor were there any lawsuits related to the environment.

- JTEKT has been implementing a focused confirmation of omission of facility notifications by the company-wide secretariat since FY2021, and the confirmation of all business sites except Tokushima has been completed. Confirmation at all of business sites will be completed within FY2023.

To collect information and roll it out even for cases that are even more minor than environmental near misses, JTEKT has established standards for quasi-environmental near misses, gathered information, and is working to prevent the occurrence of similar cases.

Environmental patrol by plant managers

As part of our initiatives for Environment Month every June, plant managers of all plants conduct environmental patrols.

In FY2022, the patrols were carried out with a focus on grasping and improving the plants' environmental risks.

Hanazono Plant

Emergency drills

JTEKT performs regular emergency drills to prepare for the occurrence of various environmental incidents. As an example of what was done in 2022, the Hamura Plant conducted a drill on abnormalities with its cogeneration system.

Wastewater treatment plant management level improvement WG

A working group was newly established in FY2022 to improve management levels. The meetings were held twice this fiscal year, in November and March, to identify problems with operators at each business site and discuss and share solutions.

Environmental audits

Internal audits

TEKT conducts internal audits annually using the audit check sheet to make sure of the operational status of our environmental management system and compliance with legislation. In FY2022, in order to improve the competence of internal auditors, we reviewed the audit check sheet, selected high-priority contents, and conducted focused audits. With regard to the law, we performed pre-inspections and were able to do proper auditing. JTEKT also regularly holds new auditor training sessions that are extended to our domestic group companies.

External audits

In April 2022, JTEKT underwent an ISO14001 renewal surveillance audit. The result was that there was zero case of non-conformity, and confirmed that our environmental management system was consistent with the standard requirements and were effectively implemented.

In regards to the 5 cases identified as having room for improvement, all cases have been corrected.

In the JTEKT Group, all 17 domestic companies and 31 overseas companies have been certified.

Based on the ISO14001 standard, JTEKT will regularly undergo audits, take appropriate corrective actions for indicated matters, and strive to improve the environmental management level.

Environmental education

Environmental awareness education

During Environment Month in June 2022, an environmental awareness training was provided for all employees through e-learning. In FY2022, about 160 participants took the course on the theme of "Current Status and Challenges of Japan's Energy Policy Toward Carbon Neutrality."

Education for affiliated companies

JTEKT aims to achieve carbon neutrality for all products, including those of its suppliers, by 2050. In FY2022, in addition to sharing examples of improvements made by JTEKT and its suppliers, JTEKT held a tour of the JTEKT Hanazono Plant and invited major suppliers to participate and learn about energy-saving initiatives together.

Stakeholders' engagement

Basic concept

JTEKT engages in communication activities using various means with our stakeholders, including customers, employees, local/international communities, suppliers, and shareholders/investors.

Opinions and expectations from stakeholders obtained through communication are reflected in JTEKT's environmental policies and initiatives as we further develop activities for the achievement of the targets set out in Environmental Challenge 2050 and the improvement of corporate social value.

Environmental stakeholders' engagement results

| Stakeholders | Main environmental communication | Stakeholders' needs and expectations | Reflection of JTEKT's environmental activities | |

|---|---|---|---|---|

| Clients・Suppliers | JTEKT's customers are automobile and auto parts manufacturers, machinery manufacturers, distributors and shops who purchase JTEKT products, as well as end users who use the final products, and suppliers are companies that supply raw materials and parts to JTEKT. | Clients

|

|

|

| Government office | Based around the world, JTEKT focuses on legal compliance as it communicates with local governments and other government agencies. |

|

|

|

| Global society | JTEKT contributes to improving sustainability of the global society through biodiversity conservation and reduction of energy consumption and waste emissions to reduce environmental load. |

|

|

|

| Employees | 46,053 employees work globally in the JTEKT Group. (Number of employees to be consolidated as of March 2023) |

|

|

|

| Industry | JTEKT belongs to the industry association for each business and undertakes environmental activities in accordance with each industry association's action plan. |

|

|

|

| Shareholders/Investors | JTEKT communicates with shareholders and investors through information disclosure by external evaluation, including CDP. |

|

|

|

| Local community | Based all over the world, JTEKT works as an active member of the local community. |

|

|

|

| Media | JTEKT discloses information to the media by providing company information, including information about environmental initiatives. |

|

|

|

Main activities

Community gathering

All JTEKT plants regularly invite local residents and government members for community discussions. This is an opportunity to introduce JTEKT's environmental initiatives, have participants take a plant tour and exchange opinions in order to facilitate better communication with the local community.

Partnerships with suppliers

To promote environmental initiatives with its supply chain, since FY2018, sicne FY2018, in addition to the surbey of each supplier's environmental management system development status and environmental performance targets and performance, JTEKT has been investigating their understanding status of water risks with a questionnaire, and in FY2022, JTEKT added a survey on initiatives related to the Plastic Resource Circulation Promotion Act (enacted in April 2022).

JTEKT has established "JTEKT Environmental Award System" in order to promote further improvement efforts by awarding suppliers with excellent environmental performance.

In FY2022, we honored Mitsuboshi Corporation, Asahi Forge Corporation, Yokota Corporation and Showa Seiko Corporation for their outstanding initiatives.

Initiatives with local organizations

JTEKT has been collaborating with the Nishimikawa Bird Club to develop nesting sites for little terns on the premises of the Tadomisaki Plant since 2015. Receiving advice on site maintenance, ways to attract little terns, and measures to protect chicks from birds of prey, we also host bird watching events every spring.

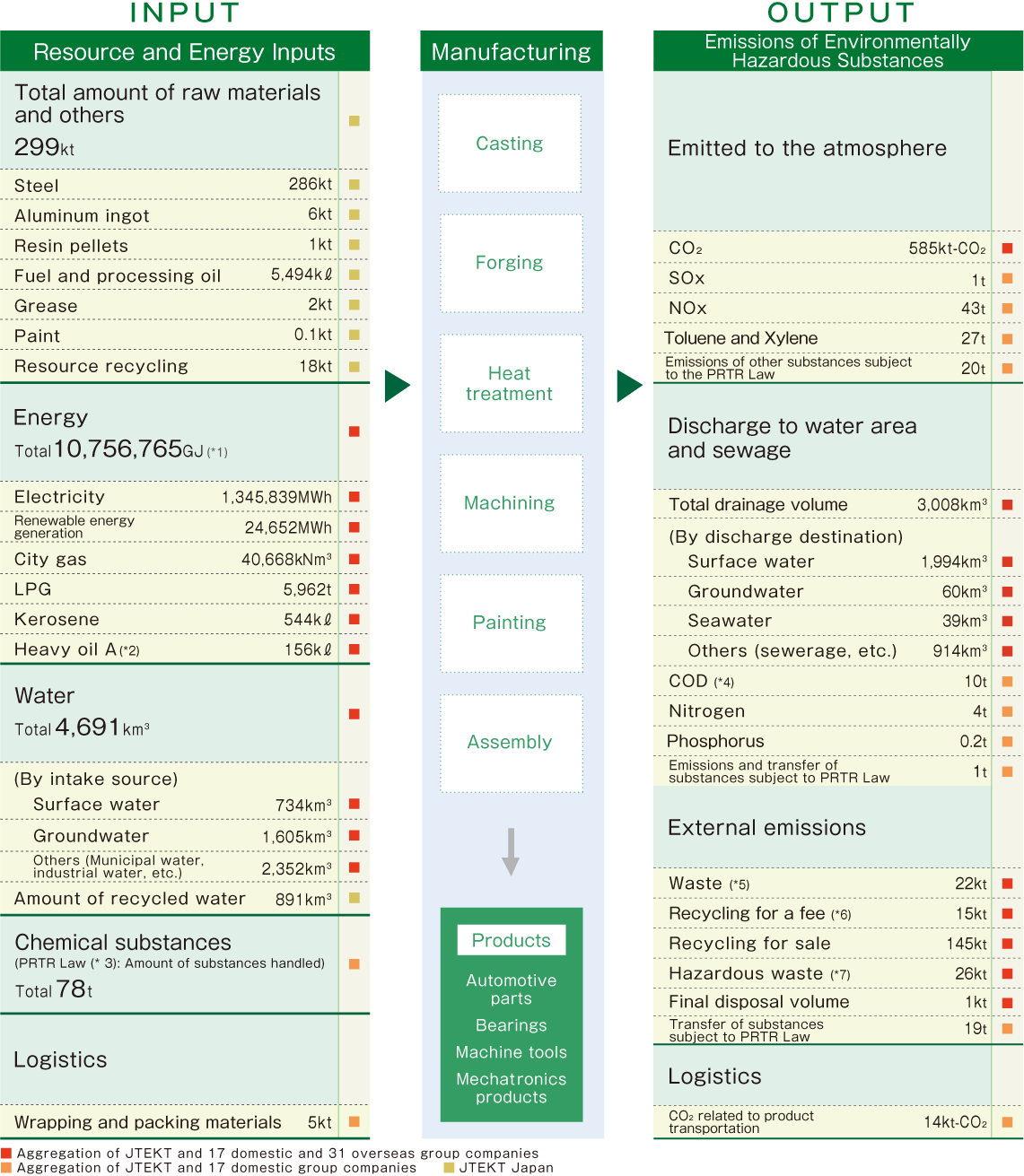

FY2022 Environmental impact flow

JTEKT quantitatively grasps its resource and energy input (INPUT) and environmental emissions (OUTPUT). To minimize the impact of global warming associated with our business activities, we are working on reducing energy consumption, focusing on processes that use a large amount of energy, such as casting, forging, heat treatment and machining.

Resource and energy inputs and emissions of environmentally hazardous substances

- *1. GJGiga-joule (heat quantity unit), G=109

- *2. Heavy oil AAmong the three classes (A, B, C) of heavy oil, heavy oil A is the closest to kerosene and is used as fuel for boilers or heating

- *3. PRTR regulation"PRTR" is an abbreviation for Pollutant Release and Transfer Register, which is a system created by the government for reporting the amount of chemical substances released or transferred

- *4. COD : Chemical Oxygen Demand (water quality index)

- *5. WasteExcluding PCB waste

- *6. Recycling for a fee : A processing fee which is required for recycling

- *7. Hazardous waste: JTEKT Japan extracts the amount of specially controlled industrial waste, while JTEKT overseas extracts the emission of substance classified as hazardous waste under the laws of each country, from the amount of waste emissions (of the number of waste and recycling for a fee)

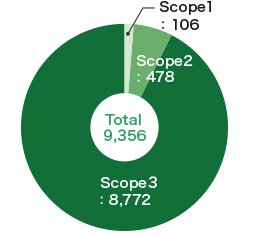

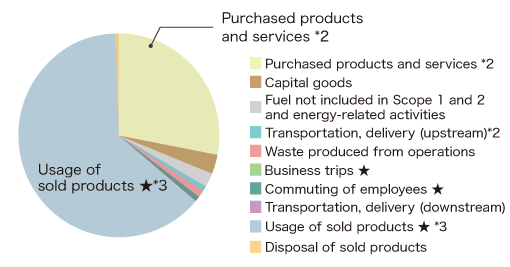

CO2 emissions throughout the supply chain

Based on the guidelines* of the Ministry of the Environment and the Ministry of Economy, Trade and Industry, we calculate CO2 emissions associated with our business activities, including the supply chain, and the use and disposal of sold products, and are working to reduce them.

* Guidelines of the Ministry of the Environment and the Ministry of Economy, Trade and Industry: Guidelines for calculating greenhouse gas emissions throughout the supply chain

FY2022 Result

| Scope (*) | Emissions (kt-CO2) |

Remarks |

|---|---|---|

| Scope 1 : Self-produced direct emissions | 106 | Self-produced emissions through using city gas and other fuels |

| Scope 2 : Indirect emissions produced by own energy source | 478 | Emissions produced due to using electricity purchased by JTEKT |

| Scope 3 : Other indirect emissions | 8,772 | Emissions produced by relational activities such as raw material purchasing, disposal and distribution |

*Scope: The calculation scope for greenhouse gas emissions stipulated by the GHG Protocol Initiative which formulates the global guidelines for calculating and reporting greenhouse gas emissions.

CO2 emissions by scope (unit: kt-CO2)

CO2 emissions by scope 3 category (ratio)

Scope 3 CO2 emissions by category (FY2022) *1

| Type | Category | Emissions | Calculation method |

|---|---|---|---|

| Upstream | 1. Purchased products and services *2 | 2,068 | Calculated by multiplying the purchase volume of raw materials (weight/price) by the emission base unit + emission volume of suppliers in Japan |

| 2. Capital goods | 215 | Calculated by multiplying the capital goods investment amount by the price base unit | |

| 3. Fuel not included in Scope 1 and 2 and energy-related activities | 164 | Calculated by multipyling energy consumption by the emission base unit | |

| 4. Transportation and delivery (upstream) *2 | 67 | Calculated by multiplying the purchase volume (purchase amount) of steel materials by the emission base unit as the emission volume related to the procurement of raw materials, parts, etc. | |

| 5. Waste produced from operations | 84 | Calculated by multiplying the waste emission volume by the emission base unit | |

| 6. Business trips ★ | 9 | Calculated by multiplying the business trip expense by the emission base unit; outside Japan, estimated based on the number of employees | |

| 7. Commuting of employees ★ | 40 | Calculated by multiplying the commuting expense by the emission base unit; outside Japan, estimated based on the number of employees | |

| 8. Leased assets | - | Leased assets are calculated as emission volume of Scope 1 and 2 | |

| Downstream | 9. Transportation and delivery (downstream) | 12 | Calculated by multiplying the product transport volume and distance by the base unit; outside Japan, calculated by multiplying the logistics expenses by the emission base unit |

| 10. Processing of sold products | - | Since it is difficult to rationally calculate processing-related emission volume at the product delivery destination, it is currently excluded from the computing range. | |

| 11. Usage of sold products ★ *3 | 6,089 | Calculated from the energy consumption of the number of units produced annually for steering, drive products, bearings, and machine tools (calculated based on over 10 years of use) | |

| 12. Disposal of sold products | 26 | Calculated by computing the mass of each material from the material composition of units produced annually for steering, drive products, bearings, and machine tools and multiplying by the emission base unit | |

| 13. Leased assets (downstream) | - | Not applicable | |

| 14. Franchise | - | Not applicable | |

| 15. Investment | - | Not applicable | |

| Total | 8,772(kt-CO2) | ||

★ Third party verification portion

*1 Calculated using the emission base unit in the guideline

*2 Calculated for the purchase volume of raw materials and emission volume of suppliers in Japan

*3 Calculated for steering, drive products, bearing products, and machine tools

CO2 conversion factor used to calculate CO2 emissions

For electric power for both Japan and overseas, emission factors by each electric power company are used.

For items other than electric power, the emission factors of the Keidanren (Japan Business Federation) are used in Japan, and the official published factors of each region are used overseas.

Third party verification

In order to improve the reliability of our data, JTEKT underwent third-party verification by SGS Japan Inc. for our FY2022. The scope of the verification covered Scope 1 and Scope 2 emissions, amount of renewable energy, water consumption, and waste emissions, and Scope 3 - Category 6 (business trips), Category 7 (employee commuting), and Category 11 (usage of sold products) of JTEKT production sites, domestic business sites of group companies, and some overseas group companies.

Certificate of verification

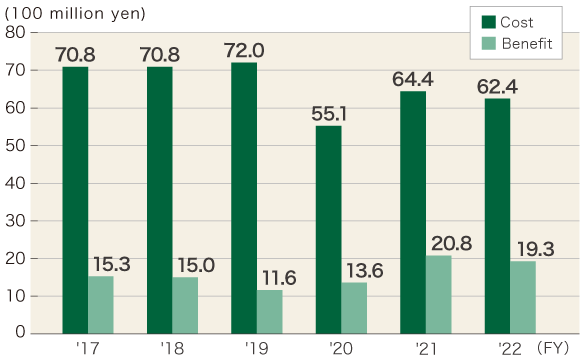

Environmental Accounting Report for FY2022

JTEKT compiles environmental accounts of the economic benefits associated with environmental conservation costs, environmental conservation effects, and environmental conservation measures in compliance with the Environmental Accounting Guidelines issued by the Ministry of the Environment. Environmental conservation costs for FY2022 were 1.78 billion yen in investments and 4.46 billion yen in expenses respectively, adding up to the total of 6.24 billion yen, an increase of 3.1% compared to the previous fiscal year.

Environmental conservation cost

(Unit : Million yen)

| Type | Details | Investment | Cost | |

|---|---|---|---|---|

| [1] Cost within business area | Environmental conservation cost to minimize the environmental impact created within each business area due to production and service activities | 554 | 1,033 | |

| Breakdown | ① Pollution prevention cost | Investment and maintenance costs related to prevention of pollution | 60 | 311 |

| ② Global environmental conservation cost | Investment and maintenance costs related to global environmental conservation (Energy-saving) | 493 | 298 | |

| ③ Resource recycling cost | Investment and maintenance costs related to proper waste treatment, recycling and reduction of water consumption | 1 | 424 | |

| [2] Upstream and downstream costs | Costs to minimize environmental impact occurring upstream and downstream along with production and service activities, and expenses involved in green purchasing, container and packaging recycling, commercialization, and contributions to industrial group | 0 | 32 | |

| [3] Management activity cost | Expenses required for environmental education, awareness-raising, maintaining environmental management system certification, monitoring and measurements, or other measures against environmental impacts | 1 | 151 | |

| [4] R&D costs | R&D costs of environmentally-friendly products | 1,221 | 3,156 | |

| [5] Social activities cost | Expenses required for disclosure of environmental information, greening activities, environmental advertising, etc. | 0 | 95 | |

| [6] Environmental damage cost | Pollution load levy (Tokyo, Tokushima), groundwater and soil remediation costs | 0 | 0.3 | |

| Total | 1,775 | 4,466 | ||

| Total amount | 6,241 | |||

Economic benefits associated with

environmental conservation measures

(Unit : Million yen)

| Details | Economic benefit |

|---|---|

| Profit from recycled material sales | 1,545 |

| Energy-cost reduction by promoting energy conservation | 366 |

| Reduction of waste processing costs | 14 |

| Total | 1,925 |

Quantitative effects associated with

environmental conservation measures

| Details | Quantitative effect |

|---|---|

| Energy consumption (kt-CO2) | 13.6 |

| Waste emissions (t) | 688 |

Cost and benefit of environmental conservation measures

- * We have not calculated the economic benefits brought about by environmental conservation activities such as increased product value, avoiding environmental risk and improving corporate image. We have only calculated items which can be accurately identified such as energy-savings benefits, etc.

- * Depreciation costs are not included. Expenses for multiple purposes are proportionately distributed.

- * Scope of calculation: JTEKT Japan (including a part of group companies working at JTEKT sites)

- * Tallying period: FY2022 (April 2022 to March 2023)

Global Environmental Management

We are working to further enhance our environmental management for 17 group companies in Japan, and 31 overseas group companies.

Europe

● 10 production companies

JTEKT AUTOMOTIVE UK LTD. (U.K.)

JTEKT AUTOMOTIVE ENGLAND LTD. (U.K.)

JTEKT TORSEN EUROPE S.A. (Belgium)

JTEKT BEARINGS DEUTSCHLAND GMBH (Germany)

JTEKT EUROPE S.A.S. (France)

JTEKT BEARINGS FRANCE SAS (France)

JTEKT Czech Republic s.r.o. (Czech Republic)

JTEKT CZECH REPUBLIC S.R.O. Pardubice Plant (Czech Republic)

JTEKT BEARINGS ROMANIA S.A (Romania)

JTEKT AUTOMOTIVE MOROCCO S.A.S (Morocco)

Asia and Oceania

● 6 production companies

JTEKT(THAILAND)CO.,LTD. (Thailand)

JTEKT AUTOMOTIVE(THAILAND)CO.,LTD. (Thailand)

JTEKT PHILIPPINES CORPORATION (Philippines)

JTEKT AUTOMOTIVE(MALAYSIA)SDN. BHD. (Malaysia)

PT.JTEKT INDONESIA (Indonesia)

JTEKT BEARINGS KOREA CO.,LTD. (Korea)

インド

● 2 production companies

JTEKT INDIA LTD. (India)

JTKET BEARINGS INDIA PRIVATE LIMITED (India)

China

● 7 production companies

JTEKT AUTOMOTIVE (TIANJIN) CO., LTD.

JTEKT STEERING SYSTEMS (XIAMEN) CO., LTD.

JTEKT BEARINGS (WUXI) CO., LTD.

JTEKT WAZHOU AUTOMOTIVE (DALIAN) CO., LTD.

JTEKT BEARINGS (DALIAN) CO., LTD.

JTEKT LIOHO AUTOMOTIVE (FOSHAN) CO., LTD.

JTEKT AUTOMOTIVE (WUXI) CO., LTD.

Japan

● JTEKT JAPAN /13 sites

● 17 domestic group production companies

JTEKT ELECTRONICS CORPORATION (Tokyo)

JTEKT FLUID POWER SYSTEMS CORPORATION (Aichi)

JTEKT COATING CORPORATION (Aichi)

JTEKT GRINDING SYSTEMS CORPORATION (Aichi)

JTEKT GRINDING TOOLS CORPORATION (Aichi)

JTEKT FORMICS CORPORATION (Aichi)

JTEKT FINETECH CO., LTD. (Tochigi)

JTEKT MACHINE SYSTEMS CORPORATION (Osaka)

JTEKT PRECISION BEARING CORPORATION (Osaka)

JTEKT THERMO SYSTEMS CORPORATION (Nara)

JTEKT METALTEC CORPORATION (Mie)

JTEKT SURPRET CO., LTD. (Osaka)

JTEKT SEALING TECHNO CORPORATION (Tokushima)

JTEKT METAL WORKS CORPORATION (Tokushima)

TYHO CO.,LTD. (Kagawa)

JTEKT COLUMN SYSTEMS CORPORATION (Shizuoka)

JTEKT GEAR SYSTEMS CORPORATION (Aichi)

North America & South America

● 6 production companies

JTEKT AUTOMOTIVE NORTH AMERICA, INC. (U.S.A.)

JTEKT BEARINGS NORTH AMERICA LLC (U.S.A.)

JTEKT BEARINGS CANADA INC. (Canada)

JTEKT AUTOMOTIVE MEXICO,S.A de C.V (Mexico)

JTEKT BRASIL LTDA. (Brazil)

JTEKT AUTOMOTIVE ARGENTINA S.A. (Argentina)

External Assessment

CDP *1

JTEKT responded to the CDP's "Climate Change" and "Water Security" surveys and received an rating A- for Climate Change and an A for Water Security which is the highest rating, in FY2022. Also, we have been selected as a Supplier Engagement Leader in the Supplier Engagement Assessment (SER * 2) for two consecutive years.

The CDP Supply Chain Program is also an important opportunity for us to engage in dialogue with our customers.

- *1 CDP: A non-governmental organization (NGO) managed by a British charity that operates a global information disclosure system for investors, companies, nations, regions, and cities to manage their own environmental impact

- *2 SER: A rating that evaluates how effectively a company works together with suppliers on climate change issues

JTEKT was elected as an "Environmental Sustainable Company" at the 4th ESG Finance Awards Japan.

The Ministry of the Environment awards institutional investors, financial institutions, and companies that have made an impact by actively engaging in ESG finance or environmental and social business, with the aim of promoting and expanding ESG finance. We have been selected as an "Environmentally Sustainable Company" for two consecutive years as a company that meets certain standards in terms of the level of disclosure in light of the screening criteria. We will continue to strive to provide more complete information disclosure.