Contribute to customers

with various solutions

of JTEKT Group

News

-

Product Technology

JTEKT developed the third-generation "High Pressure Hydrogen Valve" and "Regulator" for fuel cell vehicles.The newly developed product can be applied on fuel cell commercial vehicles.

-

Product Technology

Publishing of JTEKT ENGINEERING JOURNAL No.1019E 2023 "Special Edition on Automotive Technologies" (English version)

-

Product Technology

A paper by JTEKT employee has been published in a journal of Nature Portfolio Automated driving, Joint research with the Swiss Federal Institute of Technology

-

Product Technology

JTEKT developed the third-generation "High Pressure Hydrogen Valve" and "Regulator" for fuel cell vehicles.The newly developed product can be applied on fuel cell commercial vehicles.

-

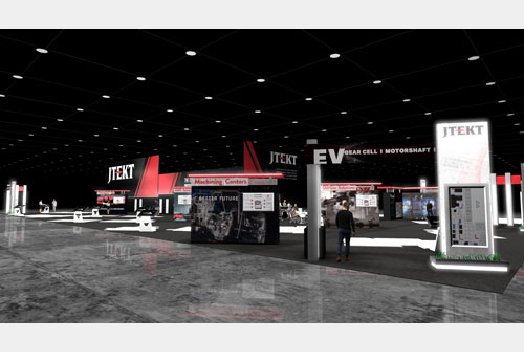

Exhibition

JTEKT Exhibit new machine tool at IMTS2022

-

Exhibition

JTEKT Corporation to Exhibitat the 46th Tokyo Motor Show 2019

Contribute to customers

with various solutions

of JTEKT Group

As social needs become more sophisticated

and diversified, we propose solutions

that contribute to our customers.

Consolidate No.1&Only One technology,

knowledge, and experience, and face

customer issues as One!JTEKT.